Glitter is widely used for decorative objects such as plastic flower and especially christmas products like balls and foam patterns etc. Glitter is thrown or rolling by hand by traditional way which is time consuming process and pretty low efficiency. The painful truth is quality is out of control and totally rely on experienced operator. Because of such weakness and uprising requirements on production, automatic solution is developped in various ways. From RPG company, we have developped a solid device which can be loaded on our robotic painting machine for automatic glitter spraying. Following will will introduce this device from indepth view for technical analyzation.

Most of existing solutions are just about how to automatic blowing the glitter by a simple device which is a modification of air blowing gun like the following

As we see, it’s basically an air blow gun attached with a glitter pot. When compressed air is sent in, glitters will be blowing out. Comparing to traditional way, it’s a big improvement for easier handling, at least the operator don’t have to touch the glitter directly and the spraying method is much more even than hand throwing. But still we need to handle by hand and final quality still depends the operator. To fully automate this process, we have developped our own glitter spraying device which is completely by program control from our painting machine.

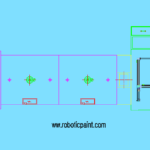

This glitter spraying device is precise production by stainless steel and alloy profiles. The nozzle design is fully compatible with various glitters and no blockage when operation. The multiple spray nozzles can be separately controlled by magnetic valves for on and off plus flow rate. This spraying head is installed on painting machine to move automatically by preset program control like paint spraying.

This glitter spraying device is precise production by stainless steel and alloy profiles. The nozzle design is fully compatible with various glitters and no blockage when operation. The multiple spray nozzles can be separately controlled by magnetic valves for on and off plus flow rate. This spraying head is installed on painting machine to move automatically by preset program control like paint spraying.

Because the spraying device is loaded on robotic machine, various programs can be set in memory for quick selection. Machine spraying speed and motion are all based fixed parameters in PLC, each data can be modified on the fly according to actual production need. Upon all these setup, the spraying quality is unbeatable high comparing any traditional ways. The most important point is we don’t need manual operation anymore for mass production requirement. Machine can be 24*7 continous running at extremely low cost.

For robotic painting machine construction details please check out this page for technical specifications, it’s a durable and flexible robot structure which can be programmed for various purposes.

The glitter spraying device is a patent development, currently it’s only offered to contracted clients. If you would like to know more about the device, feel free to contact us for further discussion.