Electrostatic spray gun is a popular device in modern spray painting industry. The biggest advantage is its affordable cost, paint and man power saving.

Electrostatic spray gun brief introduction

Electrostatic spray gun is a basic device in modern industrial spray equipment. In coating line system, electrostatic spray gun is core part of surface treatment. It’s configured to spray paint efficiently using a low-pressure high-atomizing device and an electrostatic force generated by the device.So it is a paint atomizer as well as an electrostatic electrode generator.

Working principle:

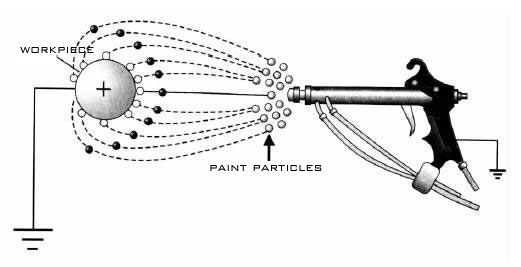

The electrostatic spray gun is based on the principle of electric spray. Object is grounded as positive electrode, paint atomization device as negative electrode, paint atomization device with a high negative voltage, forming a static electricity boundary between the two poles, atomized paint particles are charged negatively and effectively absorbed onto the object to be sprayed.

A complete set of electrostatic spray gun consists of static electricity generating device, electrostatic spray gun, pneumatic double diaphragm pump for painting and other spray accessories.

A complete set of electrostatic spray gun consists of static electricity generating device, electrostatic spray gun, pneumatic double diaphragm pump for painting and other spray accessories.

Applicable industry:

Electrostatic spray guns are suitable for: hardware parts, carbon fiber products, electroplating protection, automotive parts, steel household products, wood furniture, plastic surface coating and suitable for all conductive coatings.

The advantages of electrostatic spray gun

Traditional air based spray gun have such weakness: large amount of paint waste, serious environment pollution, difficult to clean, low production efficiency, color difference and unstable quality control etc.

Electrostatic spraying using high voltage electrostatic absorb technology, which is high efficiency, less waste, good quality, and good for workers’ health. One electrostatic spray gun efficiency is equivalent about four traditional spray guns.

Electrostatic spray gun maintenance

It is best to lubricate spray gun every day after work. Sealer, springs, needles and nozzles must be replaced periodically due to normal wearing and aging. Replacement should be carried out according to the manufacturer’s instructions. Excessive oil will flow into paint channel, causing spray defects, so be careful when lubricating.

Buying advice:

The purchase of electrostatic spray guns must be of good quality, especially for high-value sprayed objects. Good electrostatic spray gun atomizer and electrode generators are very stable. If you want to reduce the cost of manpower and material resources, it is recommended to choose from a reputable brand.

4 common misunderstandings about electrostatic spray gun

Point 1: The higher the gun voltage, the faster the powder applying, the better.

Analysis

1) According to the basic physical principle of electrostatic spraying, we know that when the charging voltage exceeds a certain value, it will intensify the “Faraday effect” and “anti-ionization effect”, which will affect the powder loading rate.

2) If the electrostatic spray gun voltage is too high, it may cause the gun nozzle to ignite, and it is easy to leave pinholes on workpiece surface, resulting in poor apparent quality.

3) High-pressure ignition will increase the phenomenon of dust burning in coating booth. Therefore, in the actual application process, we should adjust suitable voltage according to powder characteristics to obtain a relatively good spraying effect.

Point 2: A workpiece with a simple shape can work with poor performance spray gun.

Analysis

1) Some operators think the workpiece is simple shape, so there is no need for a spray gun with high performance. In fact, a good performance spray gun is not only the ability to adapt to product shape, but also the powder state control which will achieve better appearance coating and powdering rate, and the higher powdering rate will save powder and reduce cost.

2) Good electrostatic performance will also speed up production and improve work efficiency.

3) Smooth powdering will also reduce the scrap rate and make production management easier.

4) The bad performance spray gun based poor performance components used the failure rate will be much higher, even if the manufacturer repairs in time, it is inevitable to delay production. Therefore, the shape of workpiece is not the reason for selecting a spray gun with poor performance.

Point 3: sprayed powder has low transparency so spray gun has a large amount of powder flow.

Analysis

Spray gun with good charging performance can charge sufficient amount to sprayed powder particles, so that sufficient mutual electrostatic repulsion between powder particles is obtained, and powder particles are not adhered after leaving spray gun, showing a very good atomization state. From side view, we’ll see uniform transparency of the powder, resulting in the illusion of “less powder.” The powder sprayed from the spray gun with poor charging performance does not have sufficient electrostatic repulsive force between the powder particles. The powder particles are stuck together and the atomization effect is not good with low transparency. It often causes the illusion of “more powder”.

Point 4: The larger amount of powder sprayed, the higher the powder rate and the faster the work.

Analysis

1) The spray gun powdering rate is determined by the electrostatic properties and the powdering state. Only when electric field strength and powder output amount reach the ideal matching point, the ideal powdering rate is achieved.

2) The extra powder flow will affect the powder state uniformity, which is the root cause of the powder unevenness of many large flow powder spray guns. Poor powdering conditions may cause uneven coating thickness.

3) After a large amount of experimental data and practical work experience, it is concluded that spray gun powder flow rate at 450g/min will meet working demand, excessive powder will not be chargeable at all with no adhesion but falling down directly to cyclone device. It’s serious waste.

4) The electrostatic spray gun with excellent performance is developed according to the ideal ratio of electric field strength and powder output. It not only eliminates unnecessary waste, but also makes the powder flow state uniform and perfect, and improves the powdering rate. Therefore, the amount of powder flow is not as large as possible or not as small as possible.