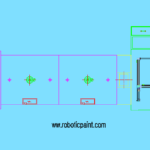

Robotic spray painting is a modern choice for high quality and high efficient paint spray production line. Though there’re various setups according to different paint documentations, the basic logic is still the same. Here we share a tipical setup of robotic painting line system by multi axis painting machine with horizontal chain belt oven dryer.

Robotic painting line process flow: Load to conveyor -> robotic spraying -> IR drying -> cooling & unload

Machine electric power: 380V /8.5KW /50Hz

Conveyor system

Dimensions: L15000*W1000*H850mm (Can be custom setup)

- 1HP digital speed regulation drive motor with gear and shaft on conveyor unload section. Load/unload area provides 1000mm operation station.

- Support structure made by 50*50*2.0T square pipe welding with powder coating treatment. Support board made by 1.0T galvanized sheet. Support frame is attached with heavy load foot cup for height adjusting.

- Stainless steel wire belt with outsized roller chain for transmission.

Robotic Painting Machine

Dimensions: L1800mm*D1950mm*H1900mm (Can be custom setup)

- Spray booth support platform made by 50*50*1.5T square stainless steel pipes

- Spray booth tank is made by stainless steel SUS304 1.5T plate welding

- Spray booth wall made by stainless steel SUS304 1.2T plate machining

- Curved water curtain by 1.0 stainless steel plate (dry filter option available)

- Water tank has height difference design for ease of cleaning and ventilation

- Stainless steel filter attached on water tank window for solid paint cleaning

- Maintenance door is installed on booth back side.

- Stainless steel nuts connection with corossion proof sealant protection

- Exhaust blower: 1 set 5.5KW centrifugal blower with inverter control

- Painting machine: 1~6 axis robotic painting machine fixed inside paint booth

- Spray gun: WRA-200 or Devilbiss automatic spray gun

- Glass window on front side for observation

Electric Control system

- 7″ colored touch screen with PLC programming

- Panasonic /Mitsubishi servo packs

- Delta inverter

- Schneider /CHNT electrical components

- 1.2T steel cabinet with powder coating treatment

- Magnetic controller for spray gun

Further more, there will be a group of pressure gauge with regulators depends the amount of spray gun installed

Paint pump: Prona /Graco pneumatic diaphragm pump

Paint mixer: 5 galon long axis pneumatic mixer with stainless steel drum

Pressure stabilizer: WolfKing stabilizer

Tubes are high quality PE/PU tubes for air and paint

IR Oven Dryer

- Dimensions: L8000*W1000*H1300mm (oven chamber is attached together with conveyor support device)

- Oven chamber is designed by L2000mm sections. These units are connected together for a tunnel type dryer

- Oven chamber is made by 1.2T steel plate with powder coating. Inner side is made by mirror type stainless steel

- Thermal insulation by 120K 100T rock wool, each chamber provides a maintenance door with rubber sealer

- On top of oven chamber, there’s a long axis fan motor for hot air mixing

- Each oven unit is powered by 6PCS stainless steel IR heater with solid state temperature controller

Aobve is a quick list of horizontal robotic painting line setup. Each part in the list can be deeply customized by specific onsite requirements such as: the sizes /available motions /oven temperature /type of conveyor belt /type of booth setup /waste air handling etc.. At RPG, we provide turnkey project service. Client only need to provide us specific needs then we will finalize the rest.