Automatic Loading and Unloading for UV Vacuum Coating

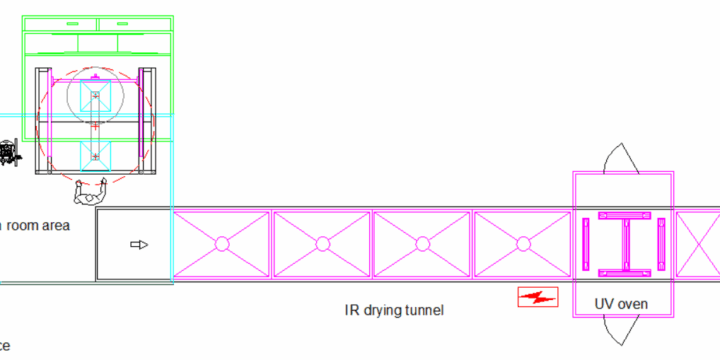

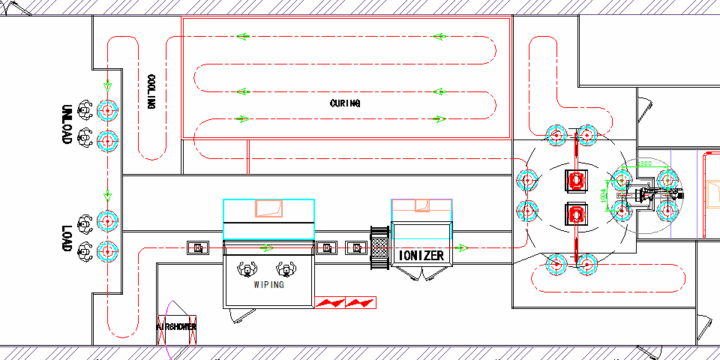

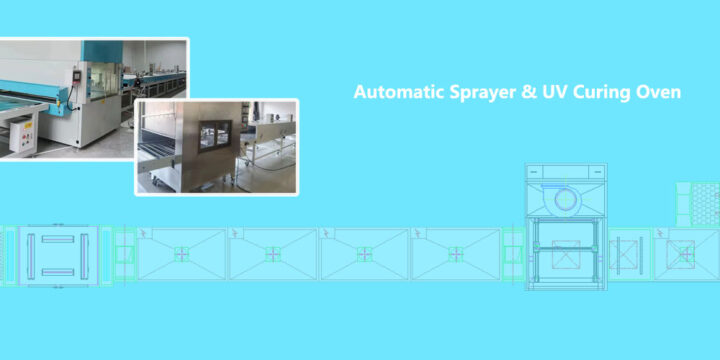

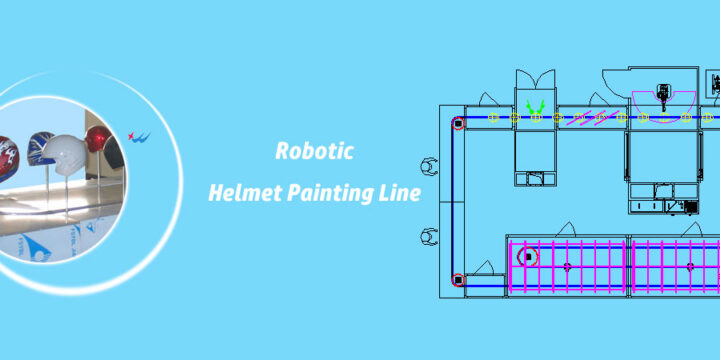

[vc_row][vc_column][vc_column_text]Automatic loading and unloading manipulator for UV vacuum coating is an automation equipment specifically used in plastic vacuum coating process via chain spindle conveyor system. It's mainly used for efficiently and accurately handling the workpieces loading and unloading between vacuum coater and uv line. The core technology lies in robotic arms, conveyor and machine vision systems to automatically identify, grasp, transport and positioning. This not only reduces reliance on manual labor but also significantly improves the continuity and stability of the production process. In coating production lines, the introduction of automated loading and unloading technology not only enhances production efficiency but also effectively improves the working environment. Automated systems can operate stably in harsh conditions, ensuring worker safety while reducing production interruptions caused by environmental factors. At the same time,…