Double Spray Arm Painting Machine

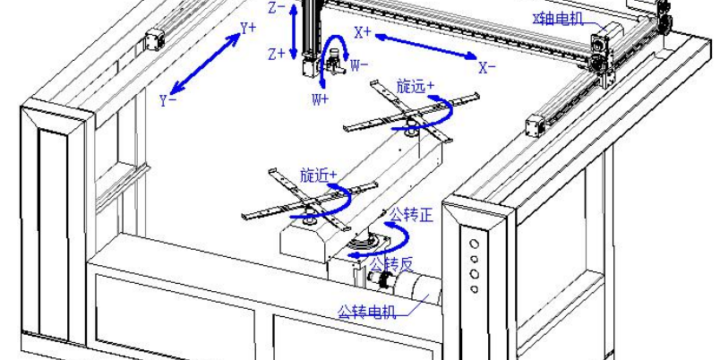

[vc_row][vc_column][vc_column_text] RPG two spray arm painting machine is a multi-station automated spray system designed for high-volume industrial coating purpose. Its core part is constructed by two sets of 6 axis spray arms but within a single support structure to achieve high-efficiency and consistent surface coating through synchronized reciprocating motion. Painting Machine Structural Characteristics Multi-station parallel spraying: The equipment is configured with two spraying devices, allowing simultaneous spraying of 2 identical or similar workpieces, significantly increasing production capacity per unit time. Motion control system: Utilizes X/Y/Z three-axis linear motion + W/R rotary axis linkage to precisely control the spatial trajectory of each spray gun, adapting to flat, curved, and irregularly shaped workpieces. Integrated paint supply system: Equipped with central paint supply, pressure regulation, and atomization control modules, supporting various coating media…