Plastic Switch Panel Painting Machine

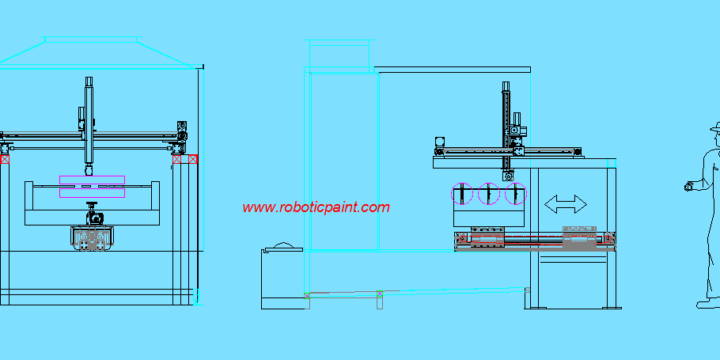

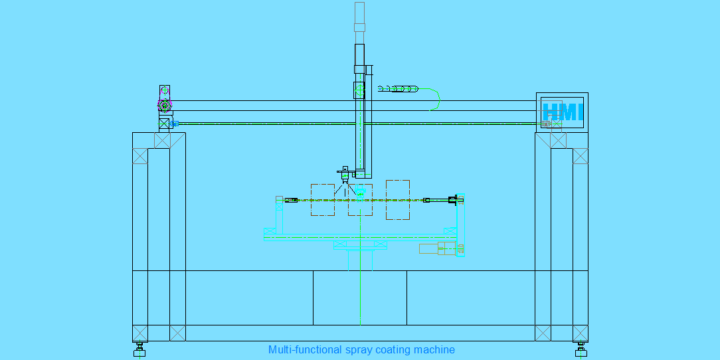

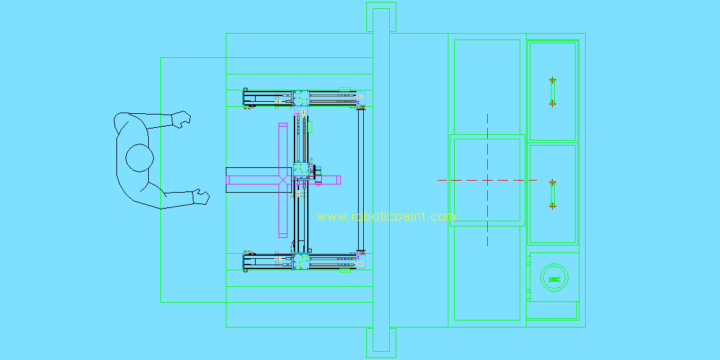

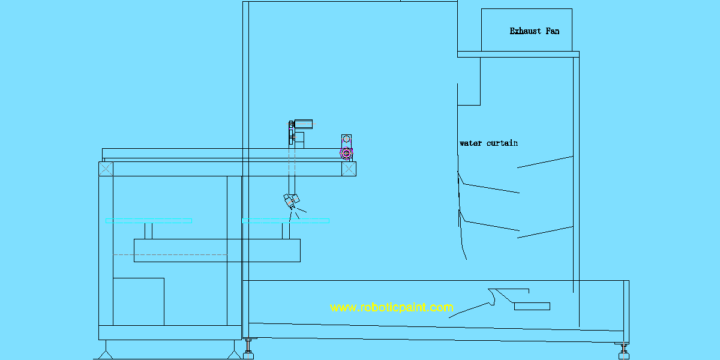

[vc_row][vc_column][vc_column_text]Plastic switch panel painting machine is widely compatible with lots of products spraying requirements from technical view. The basic and core part is our five axis painting machine. In this article, we will introduce each part from our indepth explanation and compare the available solutions for plastic switch panel painting. Because when customer have different production requirements, the spray painting solutions can be vary to meet with each unique conditions. Basically, for switch panel painting there are three parts in function - spraying machine, paint booth and drying oven. Each part can be tailored by specific production needs such as capacity, space limitation and environment policy etc. Here lets view one by one. Switch Panel Painting Machine Quick View Spraying machine L2200 x W1900 x H2200 mm NO. of…