People’s demand for diversified surface treatment has not only enriched the product variety, but also posed new challenges to the manufacturing process. The traditional spray painting line is originally designed for mass production, seems to be somewhat unable to cope with the production needs of lightweight materials (such as aluminum alloy, carbon fiber), stricter environmental protection requirements, and small batches and multiple varieties. How to make the painting line smarter, more flexible, and more environmentally friendly, and truly match the future of modern coating? Following we’ll do indepth view how to help customer achieve efficient and high-quality coating production through intelligent transformation.

The pains of traditional painting process

Traditional painting lines have exposed many shortcomings:

- Less compatibility: New products, especially ev cars, use a lot of aluminum alloys and composite materials. Traditional pre-treatment processes are difficult to ensure coating adhesion.

- High energy consumption: The energy consumption of a single vehicle on the traditional coating line is 800-1200kWh, which runs counter to the low-carbon concept.

- High environmental pressure: Solvent-based coatings have high VOCs emissions (45-60g/m²), which does not meet the increasingly stringent environmental regulations.

- Lack of flexibility: Traditional painting lines take 30-45 minutes to change colors, which is difficult to adapt to small batch and customized production needs.

These pains force the industry to upgrade – smarter, more flexible, and greener coating technology

Three major technological breakthroughs of flexible coating lines

1. Upgrade of material adaptability

Aluminum alloy: Adopting nano-ceramic conversion film technology, the adhesion reaches the highest industry standard (ASTM D3359 Level 1).

Carbon fiber parts: Innovative low-temperature plasma pretreatment makes the coating stronger and the surface energy is increased to more than 72mN/m.

2. Environmental protection process innovation

Water-based coatings: VOCs content is reduced to below 20g/L, which is much lower than traditional solvent-based coatings.

Thin film pretreatment technology: Water consumption is reduced by 60%, which is more resource-saving.

UV curing technology: Energy consumption is reduced by 40%, especially suitable for heat-sensitive components (such as battery packs).

3. Flexible + intelligent design

Fast color change system: Color change time is shortened from 30 minutes to 8 minutes, improving production efficiency.

AI visual inspection: Automatically identify coating defects with an accuracy rate of up to 99.7%, far exceeding manual quality inspection.

Digital twin technology: Real-time optimization of process parameters, shortening the debugging cycle by 70%.

These innovations make the painting line not only more “smart”, but also flexibly adaptable to different product models

| Comparison | Traditional Painting Line | Flexible Painting Line |

| NO. of Painting Booth | 1~∞ | 1 |

| NO. of Curing Furnace | 2~3 | 1 |

| NO. of AHU | Multiple | 1 |

| NO. of Spray Kit | Multiple | 1 |

| NO. of Handling Fixture | Many | 1/3 Qty |

| Installation Size | Big | Small |

| General Energy Consumption | High | Small |

| Waste Treatment | High Vol | Less Vol |

| Setup Cost | Expensive | Less Expensive |

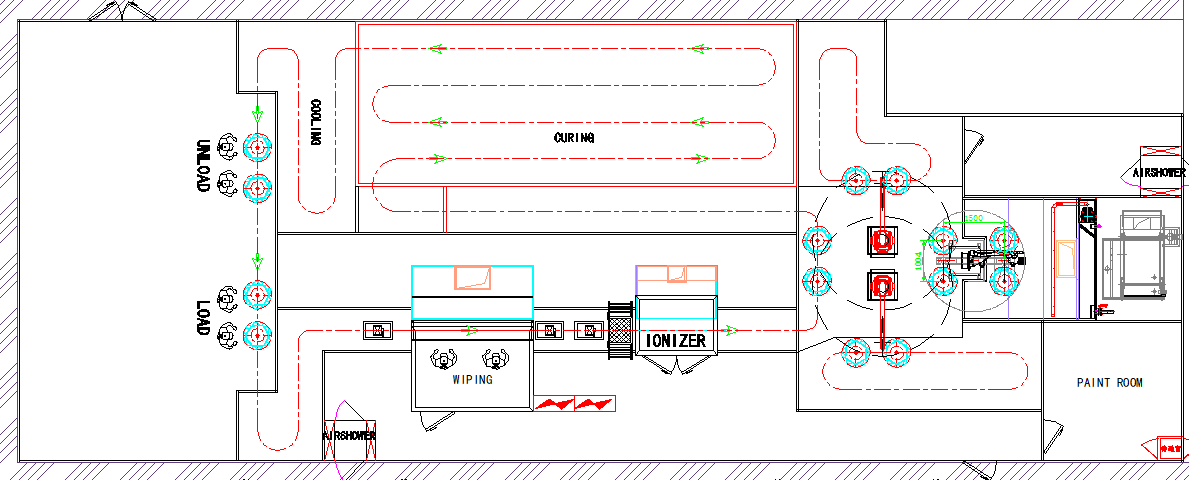

What’s included from an intelligence and flexible painting line system?

1. Digital twin system: virtual debugging, reducing trial and error costs, and reducing energy consumption by 15%.

2. AI quality inspection: hyperspectral imaging + deep learning, even micron-level defects can be found.

3. Predictive maintenance: discover equipment hidden dangers in advance and reduce 80% of unexpected downtime.

4. Intelligent spraying robot: 3D vision precise spraying, paint utilization rate up to 95%, saving materials and high efficiency!

The highlights from a flexible painting line construction is its super small installation size but be able to meet with a variety of painting process design like 1B1C /3C1B. For example, from traditional painting line structure we use 3 spray booths if we need three coats. However we can finish all from a single booth on flexible painting line. We just need to repeat the process easily with a single dryer. Because of its simple structure, the fine rate is unbeatable high (95-100%).

A single set of painting line with modular setup adapted to multiple models and different sizes of components – this is the future!

How to customize the flexible painting line? Different products have different requirements for coating, customization is the best solution!

Intelligent coating, from traditional processes to intelligent breakthroughs, more environmentally friendly, more flexible, and more efficient coating lines are becoming industry standards.