Robot is the core of intelligent painting technology, the development of intelligent painting robots is inseparable from the application of new materials, new designs and new technologies. Especially with the continuous development of artificial intelligence, machine learning and other technologies, painting robot technology has also been greatly improved.

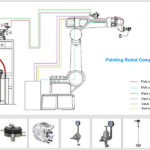

Intelligent painting robot components

Intelligent painting robot mainly includes the robot arm, control system, sensors, actuators and other components. Robot arm body is mainly composed of mechanical structure and electric control system, including the robot’s body, arms, nozzles and other parts. The control system is mainly composed of computers and related software which is used to control the robot movement and spraying process. Sensors mainly include vision sensors, force sensors, temperature sensors, etc., which are used to detect the robot’s motion status and environmental information. The actuator mainly includes nozzles, suction cups, solenoid valves, etc., which are used to realize the robot’s spraying action.

Intelligent painting robot advantages

- The profiling spraying trajectory is accurate, improving the uniformity of the coating film and spraying quality.

- Reduce the amount of overspray and cleaning solvent, improved material utilization.

- Easy to operate and maintain.

- High equipment utilization.

Development of intelligent painting robot includes the following

- Structural mechanism design optimization.

- Dynamic performance monitoring and painting system control.

- Automatic planning and adjustment of spraying trajectory.

- Research on spray quality inspection methods.

- The combination of intelligent painting robot and artificial intelligence.

With the continuous development of technology and expansion of applications, intelligent painting robot will be applied in more industries, bringing more possibilities to the development of the painting industry. Spraying technology is an application technology developed on the basis of industrial robots. The purpose is to improve spraying efficiency and consistency and reduce labor costs and human errors. Intelligent painting robot technology mainly includes the following aspects:

Control system: painting robot needs to be equipped with a corresponding control system, which is used to control the robot motion & movemen, the switch of the spraying equipment and fluid control.

Spraying equipment: painting robot is generally equipped with various spray painting equipment such as electrostatic spraying equipment, high-pressure air spraying equipment, etc. to meet different painting needs.

Sensors: painting robot needs to be equipped with a variety of sensors to detect coating thickness, uniformity, gloss and other relevant parameters to ensure the quality of the coating surface.

Software: painting robot needs to use relevant software to help run robot actions, set processing parameters, detect work areas, etc.

Safety measures: operation of the robot should follow relevant safety rules, mainly to prevent the robot from accidentally injuring people or tailoring items.

In summary, painting robot needs to be equipped with corresponding control systems, spraying equipment, sensors and software, etc., and safety measures are also required to ensure the safety of production operations. As painting robots may be used in any scene that requires spraying, especially for production lines with high safety and quality requirements. Intelligent painting robots can bring better production benefits to enterprises.