Nano Spray Chrome Painting Overview

Nano Spray chrome paintting(or nano coating) is a popular technique used in coating industry. Unlike traditional liquid based plating or vacuum metallizing, spray chrome painting is completely based spraying technologies. For mass production purpose, it can be fully automated on chain conveyor system without extra handling. Because nano coating is workable on almost any substrate, it’s widely used in lots of industries such as plastic, ceramic, glass and even metal hardware. In this article, we will explain the theory of spray chrome painting and detailed steps of application. We will also compare the different ways of metallizing for Cons and Pros.

Nano Spray Chrome Painting Theory and Application Process

Nano Spray chrome painting is basically about chemical reaction on object surface to provide a mirror like finishing. So it’s not a real metal like plating but a relatively thinner paint layer. In order to receive such finishing, we have to apply multiple stage treatment under a suitable environment.

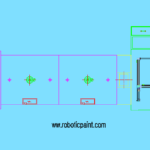

Nano spray chrome painting process flow

The general process of nano coating is this: base painting -> drying -> nano plating -> top painting -> drying.

To be more specific, the detailed process includes the following:

- – Pretreatment (such as grease cleaning or dust cleaning, we must make the object clean before spray coating)

- – Base painting (normally mixed by stannous chloride, organic citric acid and DI water)

- – DI water spraying (can be the same cabin of base painting, the purpose is to wash out extra chemicals without reaction on object surface)

- – Drying (base paint must be complete drying for guaranteed contact)

- – K1 & K2 painting by double nozzle spray gun (the most crucial part to get plating like surface. K1 agent is mixed by silver nitrate, ammonia and pure water; K2 agent is mixed by maltose, ascorbic acid and DI water)

- – DI water spraying (same like step 3)

- – Drying (to get a solid coating layer)

- – Top painting (can be a clear color protective varnish or varnish mixed with color pigment such as golden, blue, purple. Any color can be prepared by requirement to reach metal like surface)

In the process, DI water spraying is applied once after painting so it’s configured in same spray booth. Because of this, the spray booth is relatively bigger than regular painting system design. Nano coating is applied by double nozzle spray gun and mixed specially in stand alone unit. The ratio of K1 and K2 agent must be 1:1 for guaranteed quality control. Top painting can be uv coating for fast production.

Pros of Nano Spray Chrome Painting

- eco friendly, no waste pollution

- less investment, low cost operation

- easy operation, no special technical experience required

- suitable for automatic and mass production requirement

- multi color choice

- widely used in lots of industries

Cons of Nano Spray Chrome Painting

The main weakness of nano coating is the chrome layer hardness. Nano coating is by chemical reaction while plating is real metal particles so hardness is quite high. However it’s passed ASTM tests and even better than traditional painting.

Considerring all it’s pros and cons, nano spray chrome painting is quite suitable for those decoration items like toy, bottle and handicraft etc. Not just for it’s quality control but also it’s super low cost comparing to other solutions, only half or as low as 1/10 costs of traditional plating.

Conditions of Nano Spray Chrome Painting

- the operation should be done in dust free environment, nano coating should be filtered in advance by 300 mesh filter

- K1 agent normally need to keep 24 hours more after preparation

- we must use DI water with 10MΩ·cm resistivity, can not use tap water or drink water

- double nozzle spray gun fluid ratio should be 1:1, distance to object 20cm

- compressed air must dry and oil free

Problems and Solutions of Nano Coating

Solution: workshop temperature too low or spray gun nozzle ratio not equal, please refer to above application conditions.

Solution: the base paint is not completely dry or top painting thinner not compatible. We must give sufficient drying time and use suggested thinner and prepare by required ratio.