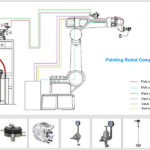

Painting robot is a type of industrial robot which consists of three major parts and six subsystems. The three major parts are: the mechanical body, the sensor and control part. The six subsystems are: drive system, mechanical structure system, perception system, robot-environment interaction system, man-machine interaction system and control system. Following we will provide a detailed introduction over the six subsystems.

Drive system of painting robot

To make the painting robot run, a transmission device for each wrist(freedom of motion) is installed, that is the drive system. The drive system can be hydraulic, pneumatic or electric, or a comprehensive system combining them. It can be directly driven or indirectly driven through mechanical transmission such as synchronous belts, chain and harmonic gears.

Mechanical structure of painting robot

Painting robot mechanical structure system consists of three parts: the base, the arm, and the end effector. Each part requires several degrees of freedom to form a multi-degree-of-freedom mechanical system. If the robot base has a walking mechanism, it is a walking robot; if the base does not have a walking and waist turning mechanism, it is a single robot arm. The arm generally consists of the upper arm, lower arm and wrist. The end effector is an important part that is attached to the wrist, and it can be a two-finger or multiple-finger gripper.

Perception system of painting robot

Painting robot perception system is composed of internal sensors and external sensors. Its purpose is to obtain both internal and external environment information and send back the information to robot control system. Internal sensors are used to detect variables such as the position and speed of each joint, then feed back to the closed-loop servo control system. External sensors are used to detect variables between the robot and surrounding environment, such as distance, proximity and contact conditions, etc., and are used to guide the robot so that it can identify objects and make corresponding processing. The external sensor enables the robot to obtain the surrounding environment more accurately, and on the other hand, it can also play the role of error correction.

Painting Robot Environment Interaction System

It is a system that realizes the interconnection and coordination between the painting robot and the equipment from external environment. The painting robot is integrated with external equipment into a functional unit, such as processing and manufacturing unit, welding unit, assembly unit, etc. It can also be multiple robots, multiple machine tools or multiple parts storage devices that are integrated into a functional unit to perform complex tasks.

Control system of Painting robot

The task of painting robot control system is to obtain the feedback signal from the sensor according to the robot’s operation instructions, and control the robot’s actuator to complete the specified motion and function. If the robot does not have information feedback features, the control system is called an open-loop control system; if the robot has information feedback features, the control system is called a closed-loop control system. This part is mainly composed of computer hardware and software. The software is mainly composed of human-computer interaction system and control algorithm.

Human-computer interaction system

Painting robot human-computer interaction system is a device that enables the operator to participate in the robot control and communication with the robot. For example, the computer standard terminal, the command console, the information display board, the danger signal alarm, the teaching box, etc. To be simple, the system can be divided into two parts: command given system and information display device.