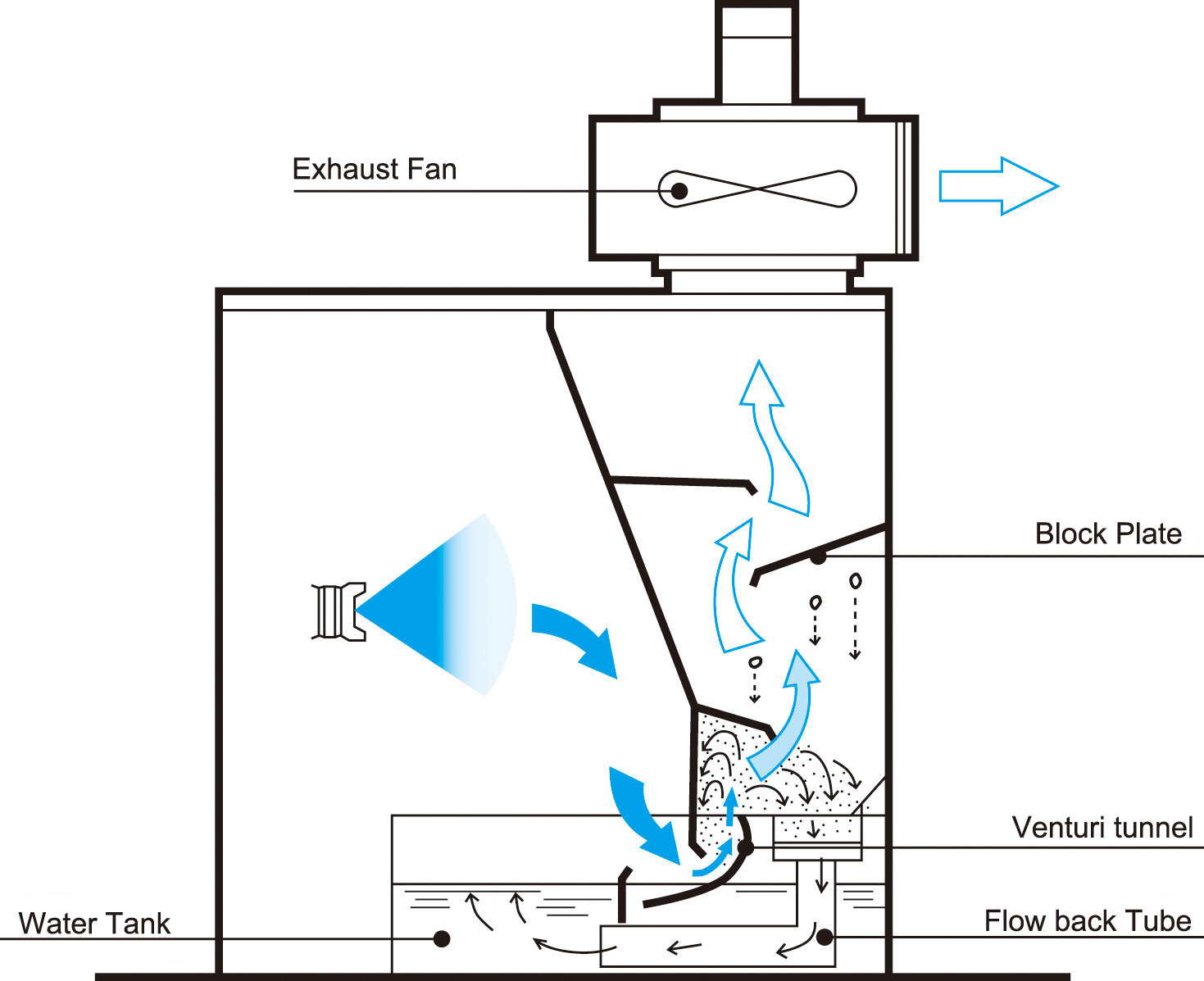

Venturi spray booth is a water type spray booth design by venturi principles for paint application. Under this design, the air flow will form a special votex like area behind water curtain. Waste paint will be catched in water and flow back to tank, thus very few waste air will come into atmosphere from exhausion fan. Venturi spray booth was initially developped by IWATA company for automotive coating at early ages.

Venturi spray booth advantages:

- High efficient paint filtering

- Ease of cleaning and maintenance

- Explosion proof option

- Stainless steel construction for extremely long life cycle

Booth specification data:

| Content |

Model |

|||||

| VB-15D | VB-20D | VB-25D | VB-30D | VB-40D | ||

| Filter Efficiency(%) | Melamine resin coating |

97 |

||||

| Nitrolac |

96 |

|||||

| Acrylic coating |

93 |

|||||

| Polyurethane coating |

95 |

|||||

| Noise (dB) |

1.5m front side | 84 | 84 | 85 | 86 | 88 |

| 1.5m left/right side | 79 | 76 | 78 | 80 | 84 | |

| Exhausion | Type |

Centrifugal |

||||

| Model | #3 | #4 | #4 | #4 | #4 1/2 | |

| Air vol (m3/min) | 110 | 145 | 180 | 215 | 290 | |

| Motor | 380v | |||||

| Output(kW) | 3.7 | 5.5 | 11 | |||

| Maintenance window | 2 | 4 | ||||

| Booth color | Stainless steel color | |||||

| Fluid volume(L) | 890 | 1195 | 1480 | 1780 | 2365 | |

| Weight(kg) | 640 | 740 | 850 | 880 | 1200 | |

| Working weight(kg) | 1530 | 1935 | 2330 | 3320 | 3565 | |

Dimensions

| Content |

Model |

|||||

| VB-15D | VB-20D | VB-25D | VB-30D | VB-40D | ||

| Dimension (mm) |

Front width(W) |

1500 |

2000 |

2500 |

3000 |

4000 |

| General depth(D) |

2000 |

|||||

| Tank depth |

1500 |

|||||

| Chamber height(h) |

2000 |

|||||

| Total height(H) |

2890 |

2890 |

2995 |

2995 |

3100 |

|

| Exhaust Fan (mm) |

Fan center height(H1) | 2357 | 2357 | 2385 | 2385 | 2412 |

| B | 390 | 460 | 460 | 460 | 500 | |

| C | 437 | 510 | 510 | 510 | 550 | |

| E | 285 | 325 | 325 | 325 | 364 | |

| Flange size(F×G) | 572×386 | 652×441 | 652×441 | 652×441 | 730×496 | |

With Robotic Paint Group LLC, we have optimized the setup in further steps. Either from the construction materials or the way of liquid cycling or the general performance, it works more nicely to meet with the modern production requirements.

RPG Venturi spray booth improvements

Spray booth material – it’s completely SUS304 including the booth tank and chambers. It’s properly machined and welded with minimal fault toterance. All stainless steel plates are lasered for precision control

Water curtain – we constructed front side water curtain board to have better filtration for over sprayed paint and also better to maintain a clean environment.

Water cycling – we redesigned the water tube system by vertical under liquid water pump plus an extra water spraying device inside exhaust tunnel. This further reduced waste paint in exhausted air

Solid wastes cleaning – we prepared a solid wastes cleaning tank behind spray booth. There’s a mesh filter to ensure water flow and extra solid wastes will be sinked after this filter. Maintenace people will easily take out the wastes by schedule

For further construction details or a tailored spray booth design, please contact us for quick solution.