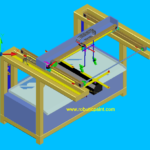

2 axis spray painting machine be able to spray by “Z” shape via two moving guides. In this way, the machine be able to paint big size product efficiently and accurately. It can be setup as dedicated unit or together with coating line for full automatic operation.

2 axis spray painting machine be able to spray by “Z” shape via two moving guides. In this way, the machine be able to paint big size product efficiently and accurately. It can be setup as dedicated unit or together with coating line for full automatic operation.

Machine is mainly composed by X & Y axis with following specifications:

- X, Y axis are high quality heavy type linar guide.

- X, Y axis are branded servo motor drived with accurate speed control.

2 Axis Machine details

| Item | Specs |

| Dimension | L1300×W1300×H800mm(Can be produce by request) |

| Products | Product max length 600mm long on tray. |

| Installation | 1, Online detective painting; 2, Dedicated unit for offline painting. |

| Spray gun control | Left/right and back/front, multiple guns can be configured to spray complex angle products |

| Motor | Panasonic servo motor |

| Linar guide | Branded liner guide and Megadyne blet |

| PLC & Touch screen | Omron or Mitsubishi PLC and Weinview touch screen |

| Power | 2KW |

| Spray gun | IWATA or Devilbiss, optional choice |

| Gun type | Optional choice with different nozzle diameters |

| Pump | Diaphragm pump |

| Product scope | Flat or arc surface products such as DVD case, phone case, pad panel etc |

| Recommended equipment | Mesh conveyor, spray booth, dry oven. Dust removal and clean room is required for high quality painting |

| After service | 12 months (human error not included) |

| Advantages | 1.High efficiency with great man power saving and quality improvement. Can be continuous operation by conveyor. 2.Automatic control by touch screen. 3.Servo motor driven for accurate positioning and fast painting. 4.Easy and user friendly programming to different products. 5.Modulized structure for quick assembly. |

2 axis spray painting machine FAQ

What kind of coating is suitable to spray?

Our machine is setup for general use of available coatings such as PU, UV and PE etc. For some specific coatings, you just need to replace the spray gun and it will work properly.

How do I operate this machine?

The machine is setup for full automatic spraying. You just need to control the system by touch screen. If you have fixed sizes products, we can set all programs in our factory so you don’t have to programming by yourself.

What kind of equipment can you offer to work with this painting machine?

We offer full coating line solutions other than this painting machine. Equipments we can offer include: spray booth, automatic conveyor, dry oven, clean room system, fresh air supply and waste gas treatment system.

How do I verify the functionality?

Before delivery to client workshop, we’ll notify customer to bring product samples to our factory and do testing. We will ensure zero problem from client side.

In need of our Two Axis Spraying Machine?

Find more about our machine construction details or send us your enquiry now to find out what we can do for you!

Dear sir/madame,

Good day. I am currently surveying for a 2 Axis Spray Painting Machine. My company is based in Shah Alam, Malaysia. Your standard dimension (L1300×W1300×H800mm) is good enough for our company’s usage. Can I have a standard quotation for the painting machine mentioned above?