3 axis spray painting machine is advanced setup for automatic spraying solution. The machine is precise production by serious material selection. The backend is a group of smart people with 10+ years machinery development experience. Either the machine structure or UI interface is fully optimized so you can install anywhere and no professional knowlege required to operate it.

3 axis spray painting machine is advanced setup for automatic spraying solution. The machine is precise production by serious material selection. The backend is a group of smart people with 10+ years machinery development experience. Either the machine structure or UI interface is fully optimized so you can install anywhere and no professional knowlege required to operate it.

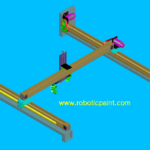

3 axis spray painting machine details:

- X/Y axis are branded linar guide and motors

- X/Y axis are drived by branded servo motors with accurate positioning.

- Z axis is a stainless steel tube for height adjust.

- D axis(for offline machine) is for rotation unit by speed controller. 90 degrees for each rotate.

- One control box with touch screen operation. An emergency stop button installed.

Machine specifications:

- Popularly used in painting industry for high quality and high efficiency production. Multiple trays can be designed to spray up to 8 products concurrently.

- Computerized digital control, be able to store up to 100 programs in memory. Friendly UI interface design.

- No professional painting operator required, stable quality guaranteed.

- Easy to programming by touch screen. Can be completed within 15 minutes.

- Continous or step forwarding operation models both available(Z and E type spray methods

- Product holder is rotatable unit, spray area is completely covered in spray booth for easy cleaning and less pollution.

- Coating atomizing, sizes and coating supply are fully controlled by remote PLC.

- Scope: popularly used for hardware, plastic and electronic products painting.

3 axis spray painting machine FAQ

3 axis spray painting machine FAQ

Q: How do I program for different products?

A: You can do programming on touch screen by setting needed parameters according to our manual book. We’ll also provide training on how to operate this machine in correct way.

Q: How long it takes for machine production?

A: We normally take two weeks for new machine production. If you prefer to take our standard design, we have multiple machines in stock to select from.

Q: Can I test with my product?

A: Sure, we have sample painting room so you can see exactly how it works and make sure the machine will be working properly for your product.

Q: What’s the payment term?

A: Because it’s standard machine, you need to make full payment before load to container.

Q: How will the machine be packed for shipping?

A: We use thin fim to pack each part of machine then load to wooden case. In this way there’s no contact to water or gas during transportation and make sure you can receive it in good quality.

In need of our Three Axis Spraying Machine?

Find more about our machine construction details or send us your enquiry now to find out what we can do for you!