There are many different processes for plastic painting over different materials such as nylon, PP, PET, etc., In order to reach the best quality, we must apply necessary pretreatment in advance. In this article we’ll briefly introduce popular 4 types pretreatment for plastic painting system, that is removal of internal stress, cleaning, de-dust and solving the problem of coating adhesion on plastic material.

1. Removal of internal stress

Plastic products are prone to internal stress during molding injection, and stress concentration is very likely to occur during painting process, resulting in cracks in plastic parts. Flamming or full-face treatment can be used to eliminate stress. Flamming treatment is quick and direct fix (popularly used for car parts coating such as bumper). We can also heat the plastic part below the heat distortion temperature, that is 60 °C, and keep it for 2 hr. Such process requires big size baking lines so a full-surface processing technique can be used, that is, a liquid solution capable of eliminating plastic internal stress at room temperature for 15 to 20 minutes. Be sure to dry up completely before loaded to painting machine.

2. Decontamination

The surface of the plastic parts is often stained with oil, hand sweat and mold release agent, which will make bad contact between paint and product, and the coating will crack, blister and fall off. Degreasing treatment should be planned before painting. Plastic parts are usually cleaned with gasoline or alcohol, then chemically degreased. Residual lye on product surface should be thoroughly cleaned with pure water then dry up. Depends the surface condition, we may use different cleaning agent with their own process

3. High-pressure ion air removal and dust removal

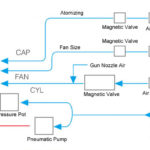

Plastic parts are insulators, the surface resistance is generally about 1013 Ω which is easy to generate static electricity. After charging, it is easy to adsorb fine dust particles in air and adhere to surface. It is very difficult to remove dust due to electrostatic adsorption by a general blowing method. Removing and discharging dust using a high-pressure ionized air stream is suggested.

4. Paint adhesion problem

Plastic materials such as nylon and PP have high surface crystallinity and low polarity. When spraying ordinary paint like rubber paint or PU paint etc., the adhesion between the substrate and paint is poor, resulting in paint falling off problem. In order to solve this problem, we can spray adhesion promoter before spraying paint. This promotor agent is to disrupt the molecular arrangement on substrate surface, increasing the dyne value, and finally solve the adhesion problem.

Lastly, in order to make stable and high quality paint film, automatic spray painting machine or robot is suggested. Not only improved the overall quality but also reduced labor cost and simplify paint shop management schedule.