Airless spraying technology principle: Airless spraying is a popular technology which is mainly used for spraying high-viscosity coatings in the fields of anti-corrosion and construction. Usually the paint is pressurized to 100-500Bar by high-pressure plunger pump and diaphragm pump then delivered to airless spray gun through high-pressure hose. At airless nozzle, due to the special design of the nozzle, when the paint with high pressure is sprayed from nozzle at high speed After the release, the hydraulic pressure is released and the friction with atmosphere is generated, resulting in violent expansion, which causes the paint to be atomized into very fine particles and sprayed onto workpiece surface.

Airless spray technology and advantages

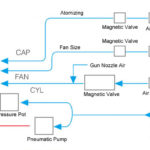

It only needs compressed air to drive the high-pressure pump to pressurize paint, compressed air does not directly contact with paint. Therefore, the pressurized high-pressure paint stream does not contain air, so it is called airless spray. The transfer efficiency (paint utilization) of airless spray is usually 40-60%. Spray flow rate can reach up to 5 liters / min.

The pressure of airless spray high-pressure pump can be adjusted. For example, the ratio of pump is 40: 1. If the airless spray pressure recommended from paint manufacturer is 200Bar, then just adjust the pump’s recent pressure to 5Bar, and the pressure will be amplified 40 times and paint pressure can reach 200Bar. For paint with greater viscosity and less atomization, we can choose a pump with greater compression ratio.

Since a single hose is connected to the pump and spray gun, spray gun cannot control the shape of spraying, the only way is to replace nozzle. Most of the nozzles are distinguished by 3 numbers. For example, a nozzle of type 521, 5 refers to fan width, angle is 50°. When it is spraying 12 inches (30cm) away from workpiece surface, width of the fan surface formed is 10 inches (25cm), 21 means the nozzle diameter is 0.021 inches (0.5mm).

Selection of airless spray equipment

Confirm workpiece specifications then select the nozzle with appropriate nozzle size (too big size will cause unnecessary waste of paint)

Confirm paint viscosity, solid ratio, coating film thickness and other parameters, select the appropriate nozzle diameter (too small nozzle will reduce the coating efficiency, and excessive sag and other defects)

Based above parameters to calculate the paint spray flow per minute and required spray pressure, then select a suitable high-pressure plunger pump!

Pump flow calculation: the flow of pump in a reciprocating stroke * 20 times! Do not calculate according to how many liters per minute the manufacturer tells you. In many cases, they are calculated based on 60 reciprocating or even free flows. In this way, this pump is scrapped in a few hours!

Pump pressure ratio selection: Usually the intake pressure of many pumps is up to 8Bar. Considering the on-site compressed air conditions, try to leave space as much as possible. For example: spraying pressure needs 200Bar. Using a 30:1 pump requires nearly 7Bar. Pressure, but the on-site air pressure may not reach to meet with spraying requirement. So we need to choose 40:1 or 45:1 high-pressure pump, so the tolerance of on-site conditions will be greater.

Airless spraying method

Hold the spray gun perpendicular to workpiece surface. Generally at a distance of 30cm, and move in parallel. The distance should be adjusted accordingly due to the type of paint and the corresponding spraying conditions.

The technique and proficiency of operator have a significant impact on final formation of the coating and the loss of paint. A good painter can save 10-20% paint.

Airless spray safety:

Because the pressure at the airless nozzle is very high, remember not to touch the body at close range. Usually, the airless spray guns adopt some protective measures such as: protective cover on the nozzle, which is basically a safe distance away from 5cm. A trigger lock is usually installed on spray gun to prevent injury caused by non-professional operations. In the event of an accident, you must go to hospital for emergency treatment. After the toxic ingredients in the paint enter the subcutaneous tissue, the consequences are quite serious!

Advantages of airless spray:

Compared with air based spraying, in addition to high pressure, paint atomization does not rely on air, but directly sprays the paint under pressure. Thus it comes with unbeatable advantages like following:

1. The production efficiency of airless spraying can be increased up to 10 times than that of general spraying (one hour about 200-600 square meters). It is very suitable for anti-corrosion coating operation of architectural decoration, steel structure, color tiles and mechanical surface.

2. The high-pressure airless spraying generates much less mist than general spraying method, and the amount of solvent in paint is also less, reduced the emission of VOC (volatile organic compounds), so pollution of paint mist and VOC is greatly reduced, labor efficiency is also greatly improved.

3. There is less paint mist in high-pressure airless spray, and paint viscosity is higher, so paint utilization rate is improved a lot, which can save paint and solvent. Compared with the general spray method, paint and solvent can save 5-25%, thus material costs are reduced as well.

4. High-pressure airless spray can spray higher viscosity materials, such as latex paint, viscose paint, 100% acrylic acid, alkyd paint, fireproof paint, thermal insulation paint, epoxy zinc-rich paint etc., no need to add extra amount thinner. Paint solid content is high and paint film is thick in one time spraying. Reduced the times of spraying, saved labor costs and reduced construction cycle.

5. There is no compressed air in paint flow, which eliminates the defects of paint film caused by the impurities such as moisture, oil stains, and dust in compressed air.

The paint film has good adhesion, can generate a good paint film even in the gaps and corners. In addition, the penetrating force is strong, which can increase the mechanical engagement force between coating and substrate, coating quality is greatly improved.

Merhaba iyi günler kerry

İbrahim ben

İstanbul /Türkiye

Metal aksesuar için boyama makinası

İstiyoruz aksesuar içeriğimiz zamak ürünlerden

Düğme, çıt çıt, toka bağucu stoper v.s

Ürünlerin makinası görmek ve almak istiyoruz

Firmamız İstanbul da Ateş Metal aksesuar ibrahim ateş +90 535 981 09 71

İyi günler görüşmek dileğiyle

Zamak aksesuar dan düğme, çıt çıt, toka, agraf,

Bağucu ve stoper benzeri üretiyoruz bunları bunların boyaması ile ilgili boyama makinası almak istiyoruz bu konu ile alakalı bilgi verirseniz sevinirim Hoşçakalın

Ateş Metal aksesuar ibrahim ateş