Five axis painting machine is our most popular production model for it’s high efficiency and flexible application.. It’s widely used in plastic, metal and woodware paint spraying production lines. Further more, we can deeply custom design this machine for various functions such as picking and put. Today we will indepth introduce this machine for it’s functionality and available designs so you can quick understand how you can select a suitable design to meet with your specific spraying requirements.

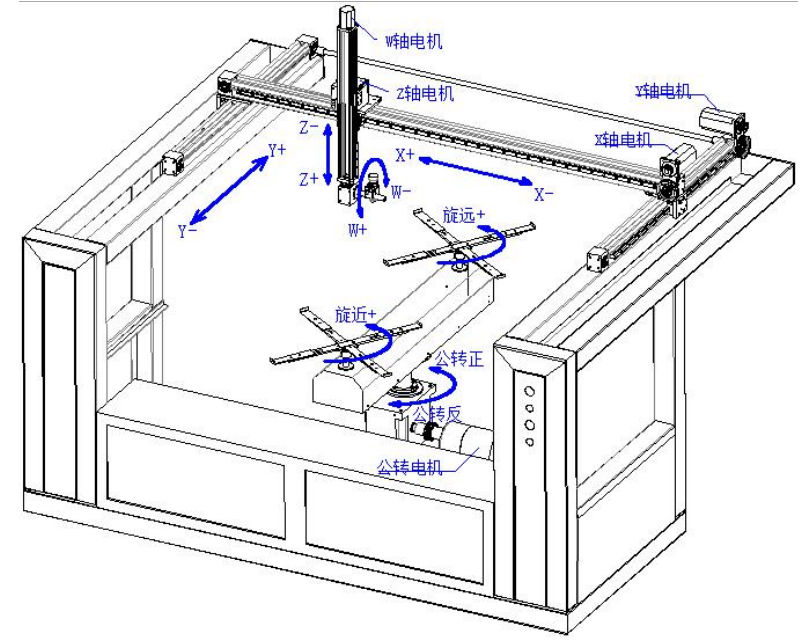

Five axis is referring its 5 motion units X/Y/Z/R/W which is powered by servo packs with PLC programming control. Each axis provides dedicated conrol for specific motioning. For quick understand the 5 axis unit, see following graphic view

This is a standard five axis spray paint machine with two support trays on a rotary table. One support tray is positioned at spraying station and one at machine front side for product load/unload. When spraying, we put the object on support tray and transfer to spraying station then move spray gun through each axis motion controller to cover its painting surface properly. Here’re the motions we use mostly:

This is a standard five axis spray paint machine with two support trays on a rotary table. One support tray is positioned at spraying station and one at machine front side for product load/unload. When spraying, we put the object on support tray and transfer to spraying station then move spray gun through each axis motion controller to cover its painting surface properly. Here’re the motions we use mostly:

X-Y-Z: under this mode, spray gun will reciprocate left/right on support tray and continuously move forward. It’s the most popular motion which can be used in many conditions because it’s workable for lots of items especially flat pieces. Normally we turn support tray 90 degrees per spray so we can spray from different angles and ensure the best painting quality.

X-Y-E: The only difference to above motion is spray gun does not move forward continuously but step forward by specific distance. Spray gun will stop spraying after finished reciprocating then move forward a bit then start spraying again. It’s used when we have multiple objects on support tray and don’t want to waste paint on blank areas.

X-Z: This motion is used on vertical surface painting. Y axis not moving, spray gun will paint on vertical area continously.

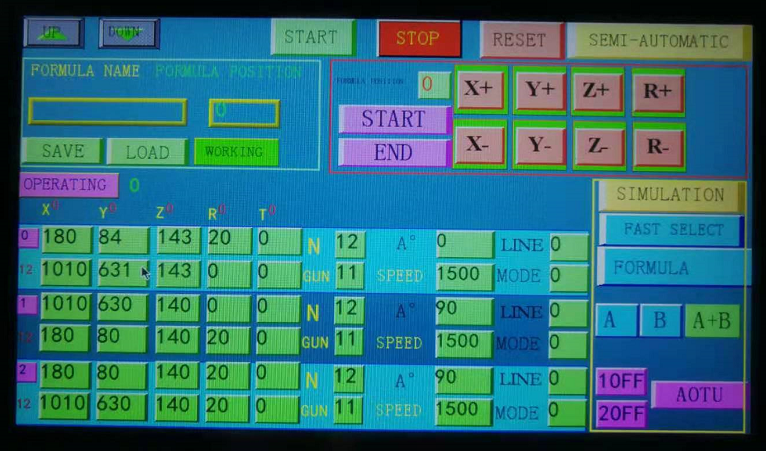

No matter which motion we select, spray gun angle can be freely input. All these operations are handled on touch screen GUI interface, see following

Five Axis Painting Machine Custom Designs

So beside the basic support tray option, what kind other designs available for our five axis painting machine? From technical view there’s no limitation how we can custom make it, but in actual production we have following models

Multi Holder

This design replaced basic support tray to multiple holders. By this way we can fix multiple objects on support holders. This is useful when we paint tall objects such as bottle and cup. See video showcase

Rod Bar

Mainly used for plastic vacuum metalizing industry. The fixture in vacuum coater can be fixed directly to painting machine so no need to transfer objects and greatly improved production efficiency. By this design, the fixture can rotate with any angle via servo control, it’s an advanced setup. See video showcase

Rod Bar & Tray together

More advanced setup than bare rod bar design. We can fix vacuum rod fixture when required, we can also put a flat support tray when we need to use traditional way. This multi functional design makes five axis painting machine very powerful to work with different production conditions. See video showcase

Moving Table & Tray

This option includes all above. Instead of a rotary table, it provides a movable option to send support tray in/out spraying station. This single spraying station can be rod bar and a flat tray. It’s used when productivity is not so high but need to handle various products with frequent change. See video showcase

Interested in our Painting Machine?

Find more about our painting machine construction details or send us your enquiry now to find out what we can do for you!