Electrostatic dust cleaning is a crucial stage for spray painting system in order to receive high quality surface finishing. Dusts on object is mainly by electrostatic absorption during production or transportation. Dust cleaning unit is to generate ionized air to neutralize static current on object and remove dusts. Following we’ll briefly introduce how electrostatic dust cleaning works and the equipment configuration standards.

Electrostatic dust cleaning is one of the most popular solutions for cleaning treatment. Static nozzle is connected with power supply (220V or 110V /input voltage 4.6KV), then connected to the ion needle through high-voltage cable, this nozzle will then generate a strong electric field, through the tip of the high-voltage corona discharge of air molecules ionized, ion needle tip to produce a large number of positive and negative ions. Then blow the ions to the surface of the charged object through compressed air, when the surface of the charged object is a positive potential, the negative ions will be neutralized. On the contrary, if the surface is negative potential, the positive ions will be in neutralized. High-speed compressed air will blow away dusts on the object.

Electrostatic dust cleaning is one of the most popular solutions for cleaning treatment. Static nozzle is connected with power supply (220V or 110V /input voltage 4.6KV), then connected to the ion needle through high-voltage cable, this nozzle will then generate a strong electric field, through the tip of the high-voltage corona discharge of air molecules ionized, ion needle tip to produce a large number of positive and negative ions. Then blow the ions to the surface of the charged object through compressed air, when the surface of the charged object is a positive potential, the negative ions will be neutralized. On the contrary, if the surface is negative potential, the positive ions will be in neutralized. High-speed compressed air will blow away dusts on the object.

Electrostatic dust cleaning advantages

- High work efficiency

- tiny to big particles can be cleaned

- Simple structure and easy to operate

- Less energy consumption

- Both manual and automatic configuration available

Corona: Under the action of electric field, the free ions in the air move to the poles, the higher the voltage, the higher intensity of electric field and faster movement of the ions. Due to the movement of the ions, an electric current is formed between the poles. At the beginning, there were fewer free ions in the air and less current. When the voltage rises to a certain value, the ions near the discharge electrode acquire higher energy and speed, when they hit neutral atoms in the air, neutral atoms break into positive and negative ions, a phenomenon known as air ionization. After ionizing and interlocking reaction, the number of ions moving between poles increases greatly, as shown by a sharp increase in the current between the poles (called corona current), air becomes a conductor. After all the air around the discharge electrode is ionized, a light blue halo, called corona, can be seen around the discharge pole.

A full set electrostatic dust cleaning unit is composed of the following:

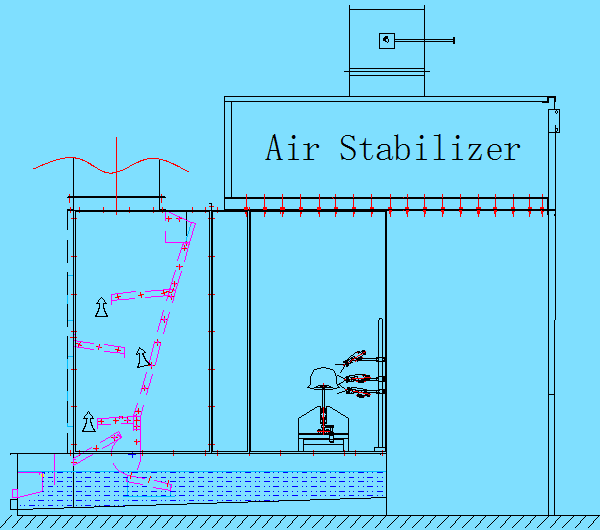

- Cabin: made by T1.2mm stainless steel, with water curtain filter or direct exhausting device

- Illumination: one set 40W explosion proof lamp

- Air stabilizer: on cabin top side to make a stable air curtain

- Electrostatic cleaning device: 8 sets STATIC ion nozzle and electrostatic generators (cleaning brush can be optional choice)