UV painting line is widely used in various industries for surface finishing such as cosmetic, electric components & automotive parts etc. Either for decorative varnishing or plastic vacuum metallization, uv painting and curing technology is popularly recognized for quick and affordable solution. With robotic paint group, uv painting line system can be tailored to meet with a variety of production requirements. Either gun fixed or robotic sprayer, we offer our client full automatic as well as semi automatic setup for high end finishing.

RPG UV painting line quick details

- Tailored design by workshop layout and production requirements

- Adjustable speed to work with different production capacity needs

- Central control for all devices without manual interruption after programming setup

- High glossy or mate UV finishing optional

- Less labor requirements to reduce general production costs

- Widely compatible with various products finishing like cosmetic container, switch panel & car parts etc.

General uv painting line procedures are followed by this technical design: load – wiping – electrostatic cleaning – flamming (optional) – promoter spray (optional) – flash off – uv spray – flahs off – IR drying – UV curing – cooling & unload

According to the painting object properties, painting line system can be chain spindle conveyor or wire belt with a suitable spray gun configuration. Semi or full automatic setup all depends the actual object for painting and setup conditions such as allocated workshop area space size, needed process and general production efficiency.

Here’s a table view between semi and full automatic line setup line specifications

| Model | Chain spindle line | General size | L30000*W20000(according to design) |

|

Electric installation

|

200KW(for reference) | Weight | ≈15000Kg |

| Material | Stainless steel | Spray method | Fixed spray gun |

| Operation mode | Full automatic | Fixture | Aluminum holder + custom fixture |

| Rotation | Friction type in paint booth area | Electric control | Central contal panel with HMI |

| Model | Horizontal belt conveyor | General size | L15000*W25000(for reference) |

| Electric installation | 50KW(for reference) | Weight | 5000Kg |

| Spray method | Robotic(reciprocator or robot) | Fixture | Plat mesh tray |

| IR oven | Straight tunnel with maintenace door | UV oven | Pass through type with flexible lamp installation |

| Paint booth | Fully closed with glass window | Control mode | Central control panel & HMI |

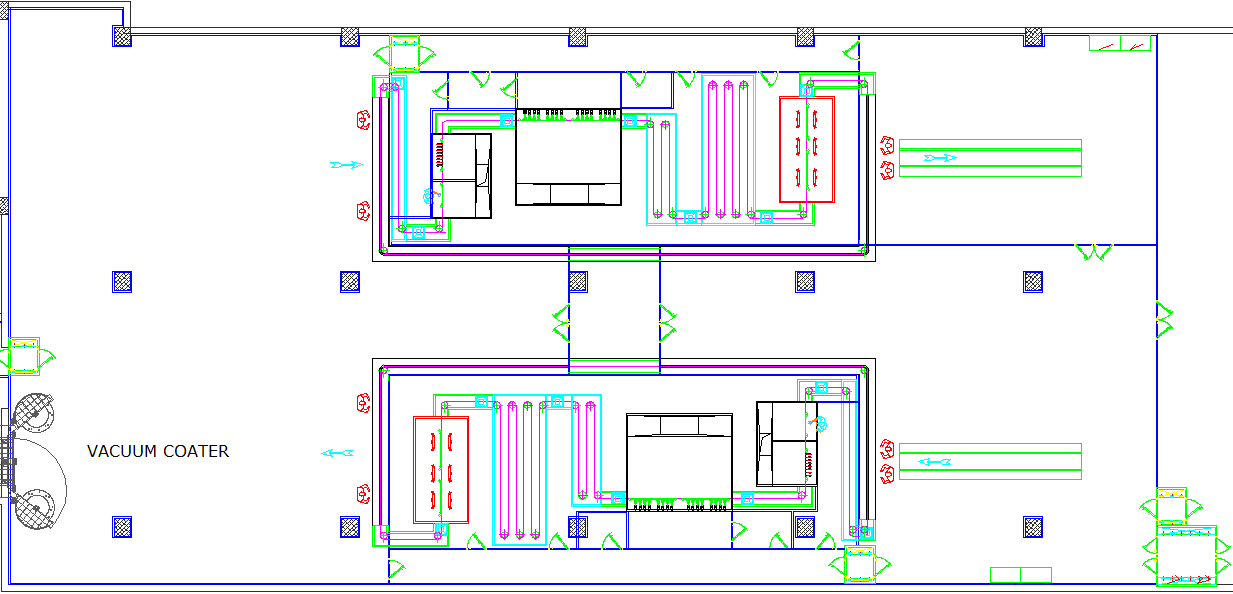

For cosmetic industry, uv painting line is always available for base painting and top painting for plastic vacuum metallization purpose. For this setup, there’re two separate lines or a big line to have the two procedures included together. Following is a diagram for reference.

As we see, the two lines are actually duplicated but it has to be for mass production needs. UV base coating and top coating are working in different principles & top coating can be mixed with color pigment for various colored metal surface finishing. Further details about this process can be found on this our tutorial article.

As we see, the two lines are actually duplicated but it has to be for mass production needs. UV base coating and top coating are working in different principles & top coating can be mixed with color pigment for various colored metal surface finishing. Further details about this process can be found on this our tutorial article.

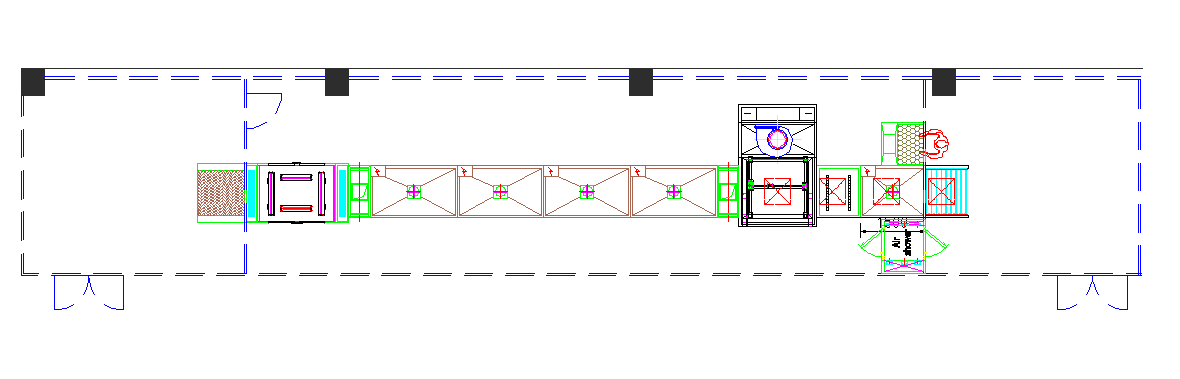

Definitely, not all objects are suitable to be processed on this chain spindle system. For those small and flat pieces, it’s hard to make a suitable fixture or it’s hard to load. Thus we have option to use a horizontal design which is easier and smaller to process it better. See follow diagram for reference

This system is constructed with a wire belt conveyor to have painting and curing quick done. Production efficiency can be easily controlled within design scope. When we have a limited space, this type consitruction should be primarily considered. Smaller size means smaller energy consumption and less operational costs.

This system is constructed with a wire belt conveyor to have painting and curing quick done. Production efficiency can be easily controlled within design scope. When we have a limited space, this type consitruction should be primarily considered. Smaller size means smaller energy consumption and less operational costs.

UV Line FAQ

Q: What kind of uv coating can be used?

An: Almost all uv coatings have similar curing conditions. Thus the actual thing we need to learn is the needed process flow of finishing. Sometimes we need coloring then uv varnishing, so we need to set a suitable thermal dryer to fit the paint drying needs. Other properties which belong to uv coating itself like high glossy or mate is just the final touch feel after curing.

Q: What’s the uv line operation condition?

An: Normally we need to configure clean room for uv line in order to ensure the maximum cleanness. Because a single tiny dust particle will be observable after curing.

Q: What other units required for uv line setup?

An: It depends the production requirements and sometimes need confirmation from customer side local policy. Especially for waste exhaust like waste air and waste water etc.

Q: How do I know what type of line is suitable?

An: In this case we will need to check customer side production requirements then suggest a suitable line setup. Some basic points like the product dimensions, treatment process and daily capacity etc are crucial for initial understanding.

Are you considering a small painting machine with affordable price? Contact us now for a tailored solution!

Interested in a UV line setup?

Call or send us your enquiry now for a tailored solution!