Linear guide is a crucial component for our spray coating machine. The moving guide choice will directly decide the machine performance, that’s why it’s considered the most important mechanical part on multi axis spray paint machine. In RPG, we will select the most appropriate mode according to different application requirements to ensure the highest accuracy and problem free operation in long time. This article we will generally introduce the linear moving guide techniques and top 5 linear guide choice.

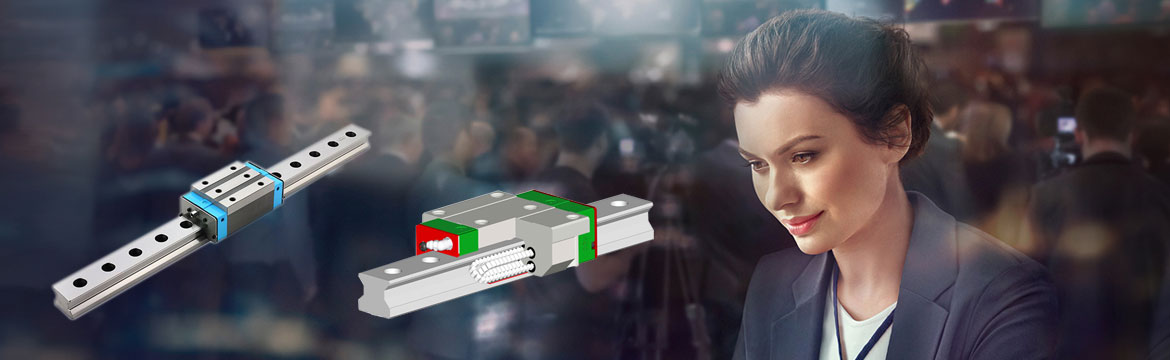

Linear guides available as recirculating ball guide and guide rail with bearing. Should I choose a recirculating ball guide or a guide rail with bearings? Before selecting the model, let’s take a look at the advantages of the two rails. Analyze to determine the right linear guide.

The first is the recirculating ball guide. Recirculating ball guides are undoubtedly the most common type of linear guides. The technology advantages in load capacity, accuracy and torque control are top consideration. However, in some conditions and applications, their advantages may become limiting. In such cases, it is recommended to choose a different solution, such as a linear guide for the factory cloud: a linear guide with bearings and induction hardened finishes. These tracks are fast and quiet, capable of handling large deviations in parallelism and flatness, providing different profiles and different anti-corrosion treatments.

Coping bias

The recirculating ball guide is a high-precision product with a high capacity to handle heavy loads in all areas. However, to achieve these results, the accuracy of the parallelism and flatness of these rail mounts must be one tenth of a millimeter. Therefore, when used for structures that are not particularly precise and/or rigid, some measures that add additional cost and time, such as fine grinding of the base surface, long and complicated mounting operations, are required. In such cases, linear guides can be a decisive solution, significantly reducing final construction costs.

Since the bearings and different profiles are made of cold drawn steel, it is ensured that the product can compensate for the axial movement of the slider in a pair of tracks up to 4 mm, while controlling the possible error of parallelism between the two planes by rotating the slider by a maximum of 2°degree. It is not difficult to see the savings that can be achieved with Cronus products when machining central door applications or any type of application where the rails are mounted on a non-machined surface compared to the assembly and process using recirculating ball bearing guides.

Working in harsh environments

The use of multiple very small diameter balls in a recirculating ball guide creates a large number of contact points between the slider and the rail. It means these rails can handle extremely heavy loads very simply and are best choice for a wide range of applications. However, in the environment where the rails are not completely clean, the presence of debris and impurities may become an obstacle that cannot be overcome by such rails: the small spheres fit tightly and cannot slide easily, and the protective shield on the slider does not provide sufficient protection and slippage. The block stops working and locks up.

On the other hand, some products have rail cleaning device on both sides of the slider, using bearings from 63 to 18 diameter. Obviously, sliders of these sizes can even efficiently cope with impurities and other types of contaminants that are critical to small spheres. Impurities are not the only source of problems with linear motion solutions. Corrosion is another major threat to many applications. Considering the field of industrial machinery, many applications are installed in humid environments or in contact with refrigerants. All outdoor applications, from the doors and platforms of special vehicles, to the underside of the train floor, and any other type of equipment used outdoors. In addition, corrosion also threatens application components that come into contact with strong acids or bases, corrosive agents, or even frequent cleaning, such as machines and automation systems in the food, pharmaceutical or medical industries.

Quiet operation

Production and industrial environments were the first to require a quiet handling system. This is a basic requirement for compliance with noise control regulations and ensuring a healthy and productive workplace. In other areas, such as medical and hospital applications, the most important requirement is to avoid any form of interference with users or patients. The use of large sliding elements with fine grinding rail ensures unique silent movement and maximum fluidity.

Linear guide Top 5

There’re many reputable brands and companies for linear guides production on the global, most of which are located in Europe. Germany’s LROSA linear guide is one of the best. Being a 100-year top linear transmission enterprise, the guide precision is quite high, and of course the price is also high, its mainly targeted for Europe and America market for high-end CNC machine, laser intelligent equipment and other top industries. According to the accuracy and life of linear guides, the following top 5 linear guides are rated through its performance and market share in machinery application:

1. German Luoshan LROSA (high precision, high price)

2. German Rexroth (high precision, high price)

The Bosch Rexroth Rexroth company is headquartered in Stuttgart, Germany. The original company was established as early as 1795, and has continued to work hard in various manufacturing technologies.

3. Japan THK (price is medium to high, high quality)

THK is committed to the development, production and sale of mechanical components such as LM Guides, Ball Splines, Ball Screws, and Electric Smart Combination Units. The LM Guide is the main product of the company and is the first product in the world to put linear rolling parts into practical applications. It makes it possible to develop high-speed machine tools with high precision, high rigidity, energy saving and long life.

4. Taiwan Hiwin (price is medium, high quality)

HIWIN is a world-renowned linear guide brand, their products include: linear guides, ball screws, linear modules, linear motors, linear actuators (electric pushers), position measurement systems (magnetic Shan), DD motor, etc. Products are widely used in CNC machine tools, woodworking machinery, handling, conveying machinery, precision measuring instruments, industrial automation machinery, electronic semiconductor machinery, mechanical arms, packaging machinery, etc., all in the field of precision linear transmission and positioning.

5. Japan IKO (price is medium, high quality)

IKO means “Innovation”, based on the high-tech “Know-how” and the originality of “Originality”. It is the longest history manufacturer, the most complete varieties and the highest level of specialization for needle roller bearing production in Japan.