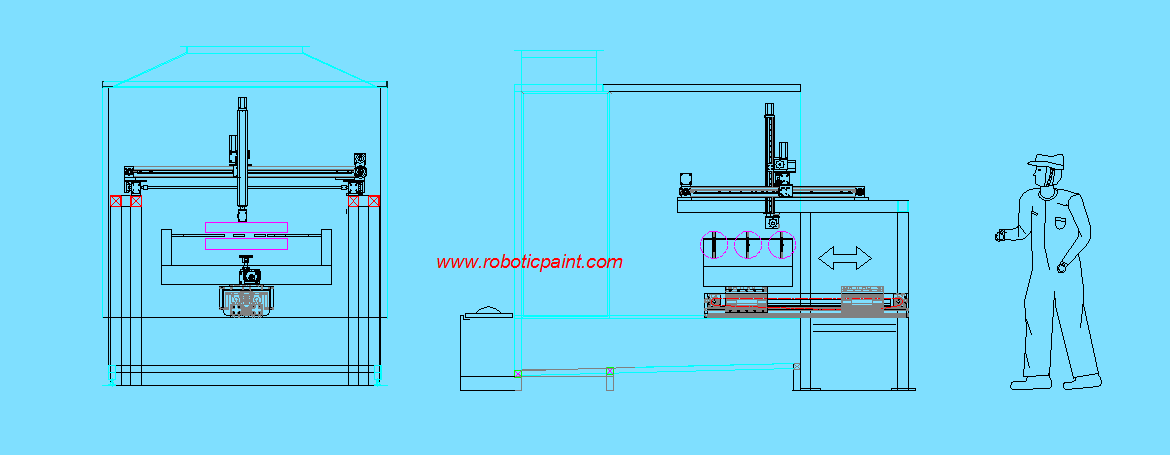

This machine is upgrade version of our multi function spray coating machine which is designed for rod bar roll by roll coating requirement. This painting machine combines functions of standard five axis painting machine and rod bar coating machine plus an moving table to send painting station into booth, then send out after properly painted. Machine is very flexible to work with various products painting requirements and can be easily setup on touch screen programming.

Multi Function Five Axis Spray Painting Machine Technical Data

| Dimensions | W1980 x D1700 x H2300mm(can be custom design) | |

| NO. of rod fixture | 3pcs rod fixture plus a flat rotary support tray | |

| Rotation | Rod continuous or with any angle rotation, flat tray 90 degrees each rotation. | |

| Spray gun | ROXGEN HVLP spray gun | 1-2 pcs |

| Axes | 5 axis | |

| Spray gun moving stroke | Axis X: 800 mm Axis Y: 800 mm Axis Z: 300 mm Rotation angle: 0-180° |

|

| Drive | Panasonic servo motors | 5 |

| Paint pump | Graco/Prona | 1 |

| Moving guide | THK linear guide | |

Machine Technical Configuration List

- Dimension: W1980*D1700*H2300mm (customizable)

- X-Y axis reach: 1200*1000mm, speed 0-1.2m/Min, Panasonic servo control

- Z axis reach: 350mmm, Panasonic servo control

- W axis(spray gun): -90—-+90 degrees adjustable

- Moving table: 1550mm long, servo control

- Rotation: fixture 360 degrees continuous rotation, servo control

- Rod fixture: 3 rods per load, Support tray 600*600mm

- Painting method: Continuous rotation or any angle rotation automatic spraying

- 1-2 pieces automatic spray gun

- A20 pneumatic paint pump

- Capacity: 30-90 sec per tray

- Control: Touch screen + PLC central control.

How does machine work?

Besides basic flat support tray like traditional five axis painting machine setup, our multi function painting machine also provides a rod holder which can be rotated for any angle under PLC programming. During spraying, holders will rotate to have pieces painted properly. Especially for those complex shaped products which is hard to reach by spray gun, this machine can handle it perfectly.

Light spot of this multi function painting machine is it includes both rod rotation and a flat support tray on moving table. When painting on rods, we can fix 3 pcs for automatic paint spraying, when painting on flat pieces, we can put a standard tray directly to holder and then it will work like a standard five axis painting machine. Support tray rotate 90 degrees each time until its properly painted. After spraying done, support tray will drive out on moving table. Operator then can take and load new pieces to repeat this process.

This multi function painting machine is powered by world class components such as Panasonic servo packs, THK precise linear guides, OMRON PLC program, Mitsubishi inverter and Airtac pneumatic units etc. Software is programmed through our years live production experience in dealing with various products from various industries like houseware, electronics, plastic and automotive. No special training required in order to operate machine like a profession.

What kind product is suitable for painting with this machine? Since its multi function design, it’s widely compatible with lots of products painting requirements like phone case, laptop panels, boxes, hairpin, christmas ball and more!

Each motion on this multi function spray paint machine is programmable on touch screen. A clean and simple screen interface is designed with no specific knowledge required for operation. Memory card can store up to 100 programs, just one click to use after machine is powered on. All programs in memory can be exported to USB storage for backup purpose.

We can also follow your product and holder size to make custom design!

Interested in our Multi Function Five Axis Painting Machine?

Find more about our machine construction details or send us your enquiry now to find out what we can do for you!