Plastic metalization are often processed through uv painting and vacuum coating for various metal materials. UV painting and vacuum metalizing are two crucial steps to get perfect metal surface on plastic. To deal with different evironment requirements, we often need to apply various tests on plastic surface. That means we must choose a propriate technique to handle with. In this article we’ll introduce the used technologies and compare the difference and advantages of the two vacuum coating solutions.

UV Painting

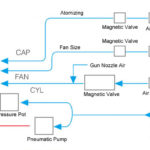

UV painting includes both base coat and top coat. Before vacuum metalizing, we must apply uv base coat first to get guaranteed contact between plastic and metal layer. Following is a typical chart of uv painting line system configuration.

This design is workable with different plastic materials such as ABS, PU and PP etc. It can be used for various plastic products painting requirements like perfume caps, shower components, houseware and automotive parts etc. After uv base painting and vacuum metalizing, we will load to uv painting line again for uv top painting. After this process, the plastic metalization process is done.

Vacuum Metalizing

For plastic vacuum metalization, there’re two popular technologies called evaporation and sputtering. They both are widely used in lots of industries. Especially aluminum evaporation which is used in almost every industries for it’s affordable and high performance design. But why sputtering? When should we use and what’s the difference comparing to evaporation. Let’s see below.

Magnetron sputtering refers to the metal placed in vacuum environment under electromagnetic field, being hit by argon to become molecules deposited on object surface, to form a uniform a pure metal surface layer.

Aluminum evaporation refers to vaporizing aluminum material atoms or molecules by heating the evaporator, forming a vapor stream, incident on object surface of and solidifying to form a solid film.

Difference between magnetron sputtering and aluminum evaporation

1- the metal effect

Magnetron sputtering can better deposit metal materils, so object surface is delicate and flat, and it is not easy to fall off, the metal effect formed by sputtering is more real and the light transmission is more uniform.

The evaporated aluminum is processed by a heated evaporator. Evaporator energy is obviously not as strong as magnetic field collision. This results in a film with a crystalline structure that is not easy to obtain, the metal effect is not so real, metal film adhesion is small and easy to fall off, and the deposition effect is relatively poor, causing some places to be bright and dark in light transmission.

2- color selectability

Magnetron sputtering can sputter a variety of metals through modulation, there are 12 colors: champagne gold, rose gold, gold, purple blue, amethyst, bright silver, etc. Oracle has even created a fog matte effect. Can meet customer various needs.

Evaporated aluminum, as the name suggests, is attached with aluminum products, and the color is only the true color of aluminum. If we need to apply other colors, we have to spray paint which is technical challenge and easy to cause color difference. The most important is sputtering can make real color from true metal while the colors by aluminum evoporation is from chemical coating mixing.

The two coating principles are different:

Magnetron sputtering coating: The process of bombarding target material with high energy ions and causing the atoms on the target surface to fly away is called sputtering. Under the control of magnetic field, sputtered atoms or secondary electrons are bound in the form of a cycloid. The target surface allows the glow to be maintained and sputtered.

The metal film adhesion and bonding effect are also different. The adhesion of evaporation coating is relative poor, but the film uniformity is good. The sputtered film is formed by high energy and the adhesion to substrate is good, but the film will have particles. That is, the uniformity is slightly worse.

Evaporation coatings are often equipped with crystal oscillators. For materials that have been calibrated, the control effect is below 10nm. On the contrary, the sputtered film will have particles, and the thickness of 10nm is difficult to achieve precise and controllable.

So basically, sputtering is more advanced technology than evaporation. But it doesn’t mean it’s better choice due to the products we work with and it’s application requirements. The sputtered metal film is partially seeped into plastic so the contact is relatively better than evaporation, so it’s working better under some bad environment. The weak point is this technology is more expensive. So we must consider more when choosing a suitable machine for production purpose.