Air compressor (commonly known as an air pump) is a device that provides compressed air. In addition to spray painting, all pneumatic tools and equipment will use compressed air with a certain pressure and flow rate as power. A typical air compressor is shown in the figure:

Air compressor (commonly known as an air pump) is a device that provides compressed air. In addition to spray painting, all pneumatic tools and equipment will use compressed air with a certain pressure and flow rate as power. A typical air compressor is shown in the figure:

Air flow control and regulation

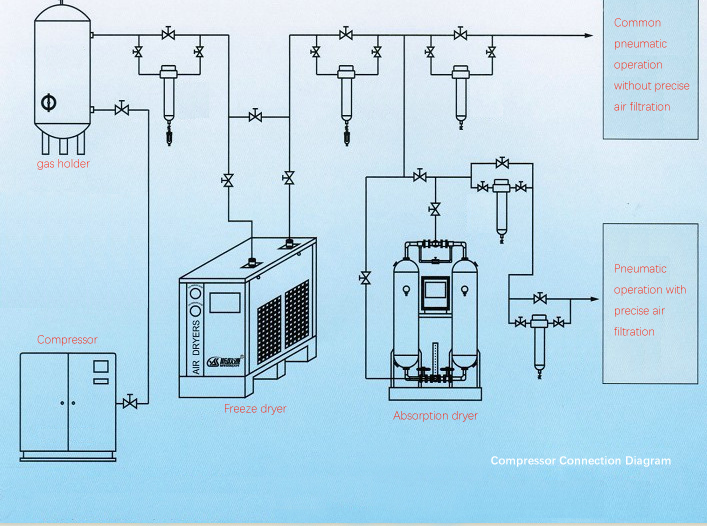

1. The air output from compressor is not directly connected to the pneumatic tool, but is transported to a gas holder and then connect to various gas application nodes through pipelines. In some air compression supply systems, in addition to the gas holder with the compressor itself, another tank is added.

The compressed air output from compressor is generally stored temporarily in gas holder. Only when the pressure of the gas in the air tank reaches the required pressure value can the pneumatic tool work normally. The gas holder is essentially an accumulator, the larger its volume, the more compressed air it can hold. Only when the pneumatic tool is in use and the pressure drops to a certain value, the compressor will start to refill the gas holder. The role of gas holder is to reduce compressor operation frequency while ensuring air supply to pneumatic tools.

2. Air handling device – Also called air-water separation regulator. It will remove moisture, oil mist and various debris in the compressed air, filter and regulate the air, adjust the pressure and provide multiple compressed air outlets for various pneumatic equipment such as spray guns, vacuum cleaners and pneumatic tools.

3. Air freeze dryer – Air freeze dryer is mainly used to reduce the temperature of compressed air. It will absorb the heat of air flow and remove impurities and residual oil and water. If the oil and water in air are not removed, it will cause the common “fish eye” phenomenon in spray painting.

4- The adsorption dryer achieves the drying effect through “pressure change” (pressure swing adsorption principle). Since the air’s ability to hold water vapor is inversely proportional to the pressure, part of the air after drying is decompressed and expanded to atmospheric pressure. This pressure change makes the expanded air drier, then it is allowed to flow through the desiccant layer that needs to be regenerated and is not connected to the air flow (that is, the drying tower that has absorbed enough water vapor). The dry regenerated gas absorbs the moisture in the desiccant and takes it out of the dryer to achieve the purpose of dehumidification. The two towers work in a cycle without the need for a heat source, and continuously provide dry compressed air to the user’s gas system.

4. Pipeline – The pipeline between the compressor and the pneumatic equipment can be made of hard pipes or soft pipes. Equipment with fixed positions is generally transported to the fixed position with hard pipes first, then connect to pneumatic equipment with soft pipes.

Compressor maintenance suggestion

Add filtration and improve equipment installation

Adding filtration equipment to the compressed air system will further improve air quality, while reducing the possibility of damage to pneumatic tools and equipment, and improving the quality of the final product

The primary filter can not only protect the dryer, but also remove the liquid/water generated in the pipeline, and remove dust to 0.5 microns, oil to 0.2 mg/m³, and the fine filter can remove dust to 0.01 microns, oil to 0.01 mg/m³. The filtration accuracy should be configured from low to high. If there is no treatment and protection of the pre-coarse filter, the post-high-precision filter element will be blocked due to excessive load, resulting in a reduced service life of the filter element. The oil-injected screw compressor should be equipped with coarse and fine two-stage filtration, and then connected to the adsorption dryer.

Use filters correctly and replace filter elements regularly to ensure high quality compressed air; drain water regularly (gas holder, filters)

Consequences of not replacing the filter element in time

- Filter element will be clogged, the filter will fail, compressed air that does not meet quality requirements will enter the system, destroying the adsorption medium of the adsorption dryer, resulting in unplanned replacement and increased user costs;

- Resulting in a smaller flow rate and higher pressure drop;

- Corroding the gas storage tank and the transmission pipeline network;

- Clogging and freezing the valve and pneumatic motor, damaging the machine and affecting production;

- Pollutants discharged from the valve and cylinder will pollute the working environment;