The Difficulty of Automatic Trace Spraying

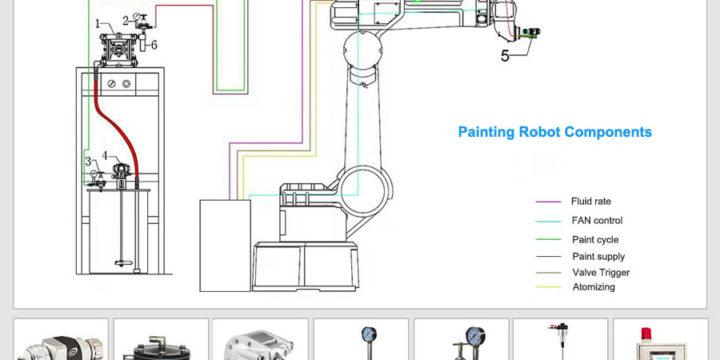

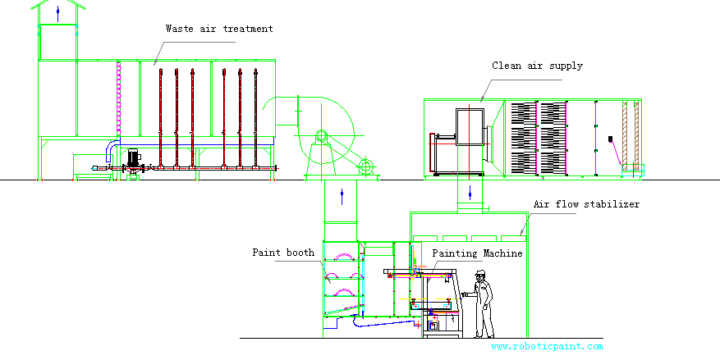

Automatic trace spraying means the spray gun will spray on loaded objects while they're moving forward on a conveyor system. The painting machine or robot will follow the conveyor speed and complete the spraying before objects move out it's effective working area. When everything setup well, it seems pretty easy. However, things are not always as expected due to various conditions. When we configure a robotic spray painting system, we always need to automate the setup as much as possible regardless the spraying method. But it's not always so easy to make it working as design principle due to technical limitation or the onsite operator skills. In this article we will briefly explain the concept and required technology in order to configure a full automatic trace spraying system by industrial…