Quick Guide of Paint Pump Selection

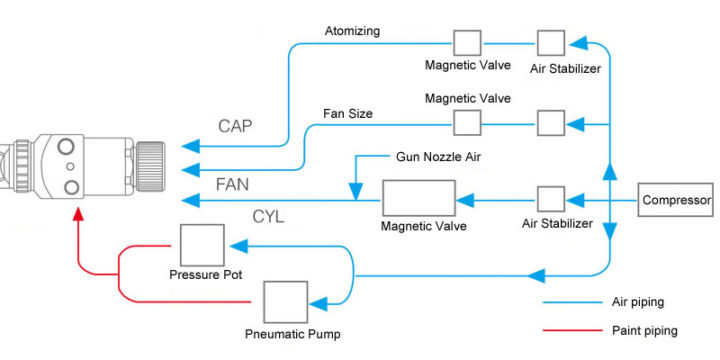

Automatic paint spraying is drived not only by a bare spray gun but also piping with backend pump system. The most popular selection of paint pump includes a pressure pot, diaphragm pump, gear pump and piston pump etc. A propriate choice will greatly help with our operation and reduce potential issues. In following section we will provide quick guidance on how to select among the different paint pumps to support our production requirements. Either diaphragm or gear pump or piston pump or even the pressure pot is widely used in painting industry, so what's the difference for each option? Let's describe using the most simple words and logic for quick understanding. Diaphragm pump - Diaphragm pumps feature a flat, diaphragm inside of a housing held together by screws. When pumping,…