Paints are accompanied by a variety of hazardous factors, whether during handling, use or during the coating process. Paints may contain hazardous substances so lassified as dangerous. Inadvertent inhalation, contact or ingestion during use may cause injury and illness. These hazardous substances also include thinners, degreasers, paint strippers and dust generated by surface treatment activities.

The main danger during spray painting process are fire and explosion, followed is by the equipment used, electricity, pressurized paint, heavy paint containers and noise.

1 – Harmful substances

Hazardous materials include paints, thinners, equipment cleaners, degreasers, paint strippers, and products for surface treatment. Exposure to these harmful substances can cause short-term and/or long-term health effects.

1) Short-term impact. Irritant dermatitis; skin and eye burns; vomiting; nose, throat and lung irritation; headache, dizziness, fatigue.

2) Long-term impact. Allergic dermatitis; occupational asthma; reproductive system damage; kidney and liver damage; “painting syndrome”, central nervous system damage caused by long-term exposure to solvents;

2 – Ways of harmful substances invading the human health

1) Inhalation and cannibalism

Spraying activities increase exposure to hazardous materials, and users are more exposed to harmful vapors, dust (dry spray), sprays (aerosols), and solvents used in cleaning processes (clean and contaminated)

Harmful substances (dust and fog) usually enter the human body through the respiratory tract and digestive tract. Exposure to harmful substances may cause acute and chronic health hazards. Acute hazards may be manifested as respiratory infections, shortness of breath, dizziness, chest tightness, nausea, headache; May be manifested as pulmonary dysfunction, respiratory disease, asthma, emphysema symptoms, central nervous system damage, and some can lead to cancer.

Polyurea elastomer material (SPUA) material itself does not contain VOC (volatile organic compounds), does not pollute the environment, does not harm human health, but the characteristics of rapid gel and high pressure operation will cause paint mist on the construction site. The particles are scattered around. If the human body inhals these solid particles, it will damage operator health; if the gel particles fall on the surrounding objects (such as: equipment, office furniture, lamp identification, etc.), it will stain the appliance and it is difficult to remove. Therefore, construction workers are required to wear protective clothing, masks and respirators; cover the surface of objects with cleanliness requirements.

2) Direct contact

Spraying, touching paint or wet painted object surfaces may also expose the skin or eye to to hazardous materials. The effect on the eyes can be manifested as a severe burning sensation. Skin contact with paints and solvents can cause acute irritant dermatitis, chronic allergic dermatitis or defatting of the skin (loss of natural fat).

3 – Fire and explosion

Solvent vapor is released during paint spraying, so the use of flammable substances (such as solvents) increases the risk of fire and explosion. The paint spray may encounter many potential sources of ignition when it spreads rapidly in the work space.

1) Open flames (flame, sparks, burning) inside or outside the workplace, fireworks, welding sparks, overheating surfaces of drying equipment, open flames when lamps are broken, heated steel plates, hot surfaces of lighting fixtures, equipment, Excessive temperature surfaces such as workpieces, pipes, radiators, and electrical appliances.

2) Electrostatic discharge. The distance between the electrostatic spray gun and the workpiece is too close. The equipment, container, pipe static electricity accumulation or container, pipe rupture, organic solvent, etc., which are used, stored, and transported, discharge the electric spark and arc generated by static electricity.

3) Friction shock. Workpieces, steel tools, and containers collide with each other. The nailed shoe soles are covered with exposed metal parts and floor impacts, etc., which can generate sparks, such as sanding grinders.

4) Electrical sparks. The circuit is opened and cut, open circuit, overload, molten metal caused by the potential difference of the fuse, fuse blown, exposed glow wire, etc., portable battery-powered equipment (such as cameras, flashlights, mobile phones, etc.).

5) Chemical energy. Self-ignition (such as linseed oil, lacquer scale, fiber accumulation and heat storage), material mixture violent exothermic reaction (such as polyester coating and initiator), organic solvent added when heating paint, aluminum powder is humidified to produce hydrogen exothermic spontaneous combustion , a two-component coating to be treated in a “can”.

6) Lightning, daylight gathering, etc. In places with limited size and poor ventilation, flammable gas and dust accumulate to reach the explosion limit, and the fire is instantaneously exploding. Solvent flash point is an indicator of fire risk. The flash point is defined as the minimum temperature at which the vapor above the volatile combustible material will burn when exposed to flame in air. The lower the flash point, the greater the fire risk.

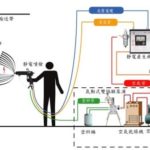

As all dangerous elements above, it’s suggested to use automatic spray paint machine or full automatic painting line system to avoid any potential health issue. The initial investment might be a little more than manual but it’s economical choice in long term consideration. Especially when referring to stable quality control.