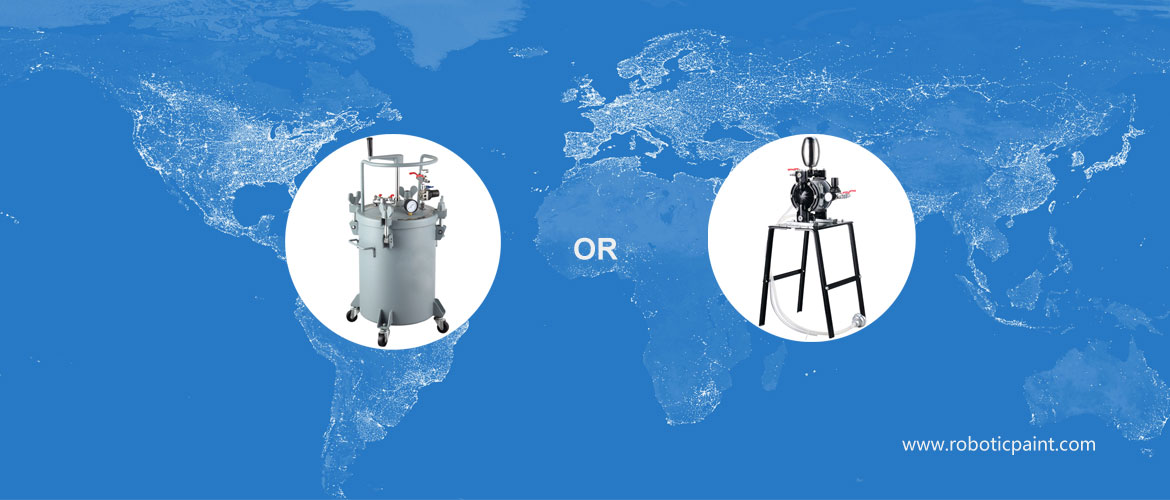

Automatic paint spraying is not a bare spray gun but multiple crucial devices such as paint pump and control system. Paint supply device is direct connection with spray gun, thus a correct selection is very important for smooth operation. Most paint spraying is supported by air based technologies so there’re two options of paint supply – diaphragm pump and pressure pot. So which one is better? In following content we will briefly introduce the two options and compare side by side from operator sight.

Diaphragm pump

The diaphragm pump definition comes under the classification of positive displacement pumps that utilize the grouping of the reciprocating operation of thermoplastic, rubber and Teflon diaphragm. The flowrates of these devices will not fluctuate much with that of discharge pressure which means the pump functions against the specified pump speed. Diaphragm pumps hold the ability to transfer either low, high or medium viscous liquids and even liquids that have extremely huge solid substances. They even manage strong chemicals like acids because they are developed with multiple kinds of diaphragms and body materials.

The most popular kind of diaphragm pump is air operated diaphragm pump and these devices utilize compressed air as the power resource. A diaphragm has two sections along with inlet and outlet check valves in every section. Through the air spool valve, circulates from one section to other and the spool valve is constructed into the pump. The circulation of air pulls out the liquid from one section and drives into the discharge piping whereas the other section is with liquid. In these devices, there will a little pulsation of the discharge movement. And this pulsation can be lessened through the utilization of dampeners in a piping way.

Advantages

- Manages even strong liquids which have high-level solid content

- They hold the ability to prime themselves

- The pump can be functioned even in dry conditions showing no damage

- As these devices function on air they are innately explosion-proof

- More flexible having only one pump but syncs up well with multiple applications

- Can be configured with a paint mixer to work together

- These devices have easy maintenance and inexpensive also

Pressure pot

Pressure Pot is designed for use in applying pressure to force air out of resin and to force resin into thin sections of a mold. This eliminates air bubbles and air traps in the cured castings. This pressure pot includes a gauge and all the other fittings

The biggest advantage of pressure pot is it’s simplity, just connect with compressed air and spray gun for quick application.

Comparison

Work principle: Diaphragm pump is by the reciprocating operation of rubber diaphragm while pressure pot is by direct air pressure to press out the paint in pot. To be more specific, it’s the same way of a manual spray gun with a pot attached.

Stability: It’s a big difference between the two. Diaphragm pump has a fluid stabilizer for stable paint supply while pressure pot completely relies the compressor condition. So if the compressor can not provide stable air pressure, the paint flow will be unstable.

Application: Diaphragm pump is mainy used for automatic paint spraying condition or where requires stable fluid rate. Pressure pot is mostly used by manual spraying and mostly for glue application.

But there’s an outstanding advantage of pressure pot, it works for any viscosity liquid and it’s very easy to use.

So based above explanation, diaphragm pump is good choice when there’s high requirements of stability, but pressure pot can be also considered for some specific conditions. When we make the choice, we need to check thoroughly and make a suitable choice.