Electrostatic DISK spray paint booth is an advanced setup in coating industry. Either for it’s spray gun and booth design or the special conveyor layout, it’s different than any other painting system. Because of its unique advantages, Electrostatic DISK spray paint booth is widely used for those complex shaped objects high quality painting system. In this article we’ll introduce each unit step by step with our actual application experience.

Electrostatic DISK spray booth quick view

- 2—3 higher efficiency when working with painting line

- smooth and high density paint spraying, greatly reduced manual spray work

- simple operation, no special training required for quick application

- inverter control of gear paint pump, stable paint supply with accurate flow control

- PLC control of reciprocator motion, speed adjustable with 6 stations to work with different products painting

- electrostatic DISK provides safety protection of overload

- all electric components are world class brands for durable and long life span

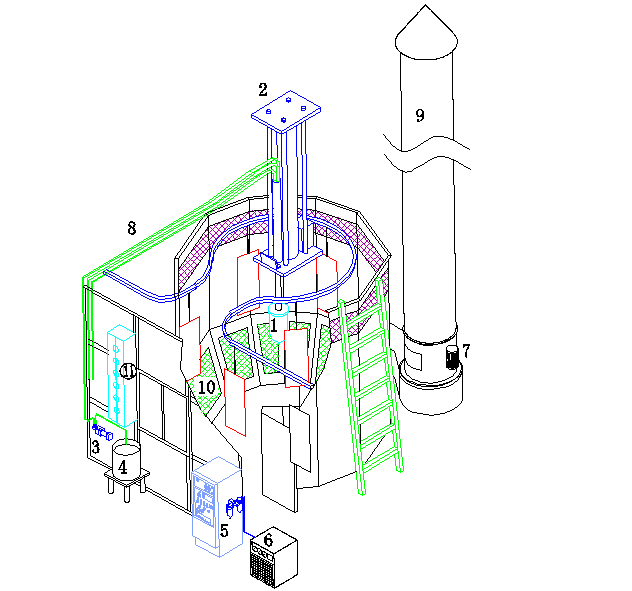

Booth chamber

Booth chamber

Electrostatic DISK spray paint booth is a round design with dry filter exhaust system. The mechanical part is made by T2.0 galvanized plates. Each plates are produced through specific design then assembled together for a reliable system. Why galvanized plates other than other maerial like stainless steel? First reason is cost consideration, material cost only 2/3 of stainless steel. Second is it’s performance, because it’s dry filter system design, there’s no water to take out the wastes, stainless steel will be hard to clean, but much easier for galvanized material as it’s nonstick.

The final finished booth system is a closed area with an entrance door for maintenance. Back side is configured with a chimney for air exhausting.

Reciprocator

Smooth and fast speed moving guide powered by cylinder digital control. Mechanical part is precise CNC production, PLC programming made it easy for central operation on touch screen.

Electrostaitc DISK spray gun

A special turbo bell with DISK type atomizer. Spray gun is attached on reciprocator for central control. When spraying, the DISK is moving up and down according to produce height, extremely atomized paint is automatically applied by electrostatic contact energy.

Paint pump

Turbo bell DISK is powered by gear pump which is perfect for paint preparation and flow control. Motor is inverter control for speed adjusting.

Conveyor

Hang conveyor is the regular design for DISK booth. Conveyor inside booth is completely followed booth design with Omega shape. This part is special setup because we have to attach a rotation unit on the guide. When products connected to this unit, it will rotate with gear so everywhere on surface can be painted properly.

All booth operation is on single control panel, either switch buttons or digital screen, operater don’t have to leave place so it’s pretty friendly for mass production consideration.