Mini robotic painting line is a small size setup which makes your automatic spray painting easier! Low cost and small size required to get started for hassle free. It’s good choice for small tand startup business who have limited budget. Regardless it’s small setup, it’s modular design provides the capacity of future upgrade. We can easily use existing components for a bigger line setup when there’s demand.

This small robotic painting line is able to serve manufacturing industries such as automobiles, furniture, hardware, plastics, wood, toys, glass, ceramics, etc. that require surface paint spraying.

Mini Painting Line Advantages

This mini painting line is simple robotic operation on touch screen plus mechanical button control, easy to fix and widely compatible with various products painting.

- Conveyorised and continuous production

- Multiple spray guns can be loaded to deal with different spraying requirement

- Easy installation and operation

- Spraying and drying without transfer for high quality production

- Easy to upgrade for bigger setup when there’s need

- Eco friendly and less maintenance guarantee!

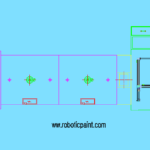

Painting line construction details as following:

| Model | PL010 | Dimensions | L6000*W3000*H2500mm(can be requested) |

|

Electric voltage

|

380V 50Hz ±10 | Weight | 3000Kg |

| Material | Stainless steel | Spray method | Robotic sprayer or fixed spray gun |

| Spraying accuracy | ±0.1MM | Servo pack | Panasonic |

| Moving guide | THK noiseless guide | Conveyor | Chain on edge conveyor |

| Spray booth | Water curtain or dry filter | Dryer | Stainless steel heater with temperature sensor |

| Oven chamber | T50 rock wool plate | Oven temperature | RT~100℃ adjustable |

| Fixture | Chrome plated holder | Drive | CPG motor with gear speed reducer |

| Chain | 50.8 outsized roller chain | Track | Stainless steel square pipe production |

| Paint pump | 5″ diaphragm pump with agitator | Spray gun | IWATA |

| Electric component | CHNT or Schneider | Pneumatic component | Airtac production |

Mini Painting Line Operation

After painting line is fixed in workshop, we need to connect compressor and electricity according to our diagram. Once it’s done we’re good to go by following procedures:

On load/unload station we put on products on fixture, when the products moves to spray booth area we need to observe and adjust each spray gun to point by required angles. Or if we choose robotic spraying, we need to make a program to make spray gun moving by required motion. During spraying, we need to make sure spray booth exhausting is powered to maintain a clean environment of production.

Curing oven must be turned on in advance since there’s wait time of temperature rising. Normally it takes up to 10 minutes to reach preset temperature. After spraying, conveyor will automatically send the painted products to run into dryer multiple times by curved track design. Once it comes out, we can pick the painted pieces at unload station.

More about painting line

Mini painting line is small but smart robotic unit to handle different spraying needs. It provides multiple ways of spraying so its very flexible to handle small to medium capacity painting condition, especially when there’s frequent change requirements. It’s widely compatible with various products spraying such as cap, lid, toy, glass bottle, cup etc. It can be easily tailored to install for any industry with painting requirement like wood, plastic and hardware parts production.

Environmental friendly spray booth design will have over sprayed paint and air during the spraying process effectively handled and filtered, greatly reducing the impact on the environment. Plus our high degree automation programming, it is easy to operate, saving labor costs and improving production efficiency.

Automatic conveyor will move painted products directly into dryer for flash off and curing. Thus there’s no need of transfer process and reduced the potential pollution over the wet surface. Its crucial for high quality protection when it’s hard for product transfer after painting.

Furthermore, the attached dryer is easy to learn and use. Temperature gauge is attached for each zone for precise control and observation, each zone temperature difference can be minimized by ±5 degrees. When the dryer is bigger design, we also have according hot mix and cycling solution to make sure each corner in oven is smooth and stable. The general layout is greatly optimized through our 10+ years development and application experience. Easy operation reduced potential hard and soft contact to machine and improved machine life time.

Are you considering a small painting machine with affordable price? Contact us now for a tailored solution!

Interested in this Mini spray line?

Call or send us your enquiry now for a tailored solution!