Paint Sprayer Overview

The spray painting machine is a special coating equipment using spraying technology. The principle is this: air flow is instantaneously pushed to paint device, pneumatic motor is stably and continuously reciprocating to have inhaled paint pressurized, then paint is delivered to spray gun on the sprayer through a high-pressure hose then atomized by the spray gun and released to the object surface for coating.

The spraying machine is mainly composed of a feeding device, a spray gun and an atomization generating source. Paint spryer is widely used in lots of industries such as leather, packaging, furniture, footwear, automobile and more.

Sprayer working principle

The main working part of the spraying machine is a double-acting pneumatic hydraulic booster pump, and the reversing mechanism is a special-type pilot-operated full air-controlled gas distribution reversing device. After entering the compressed air, when the piston moves to the upper end or the lower end of the cylinder, the upper pilot valve or the lower pilot valve is actuated, and the control airflow instantaneously pushes the valve of the gas distribution and reversing device, so that the piston of the air motor is stably and continuously reciprocated. .

Since the piston is rigidly connected to the plunger in the paint plunger pump, and the size of the piston is larger than plunger. The sucked paint is thus pressurized. Pressurized paint is sent to the spray gun through a high-pressure hose, and finally the hydraulic pressure is released at the spray nozzle then instantaneously atomized and sprayed onto the object surface to to form a coating layer.

Advantages of spraying machine

A. The paint film has good quality, the coating is smooth and delicate, and there is no brush marks. It atomize the paint into a fine particle to make it evenly distributed on the surface so that the latex paint forms a smooth and dense coating on object surface, no brush and rolling marks.

B. High coating efficiency. The single-action operation has a spraying efficiency of 200-500 square meters per hour, which is 10-15 times by manual brushing.

C. Good adhesion, long coating life. It utilizes high-pressure jetting to obtain powerful kinetic energy of the atomized paint particles; the paint particles are used to absorb the kinetic energy into the pores to make the paint film denser, thereby enhancing the mechanical bite force between the paint film and product surface thus improved the paint adhesion and effectively extend the life of coating.

D. Paint thickness is uniform and the coating utilization rate is high. The thickness of the artificial brush roller is extremely uneven, generally 30-250 micrometers, and the coating utilization rate is low; Spray coating is easy to obtain a smooth thickness let’s say 30 micrometers.

E. Easy to reach the corners and gaps. Due to the pressurised spray, the paint can easily reaches the corners, cracks, and uneven and difficult parts

F. Can spray high-viscosity coatings. High pressure airless spayer is advanced choice while hand brush, air spray, etc. are only suitable for low-viscosity coatings. For example water-based latex paint is the most popular interior and exterior wall decoration paint for its non-toxicity, convenient cleaning, rich color and no pollution to the environment. But latex paint is a very high viscosity waterborne coating. At the time of construction, the general manufacturer has very strict restrictions on the dilution of the original paint with water, generally 10%-30%. The transitional dilution will result in poor film formation. High-pressure airless sprayers can handle it perfectly.

Sprayer Types

Paint sprayer is mainly available in following: air spraying machine, high pressure airless spraying machine, air assisted spraying equipment, low flow medium pressure spraying equipment, airless spraying machine, high efficiency low pressure spraying machine and electrostatic spraying machine.

By performance, it’s grouped by: plunger type, fuel type, cart type, pneumatic type, electric type, plunger diaphragm composite type.

By manufacturing principle: plunger sprayer, plunger diaphragm composite sprayer.

Sprayer structure

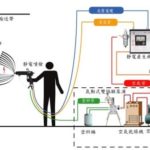

The spraying machine is mainly composed of a feeding device, a spray gun and an atomization generating source. The source of atomization varies with different types and sprayers: the atomization source of the air sprayer consists of an air compressor, a gas pipe, an air /oil /water separator, and a gas storage tank; the atomization source of the airless sprayer is powered by a power source and high-pressure pump; electrostatic spraying machine is composed of a high-frequency high-voltage electrostatic generator.

Sprayer main features

1. High efficiency – Mechanized efficiency is about 10 times than traditional manual operation.

2. Coating layer is even and smooth, and the texture is good. The coating is atomized into fine particles under high pressure, evenly distributed on product surface to get a smooth and dense paint layer;

3. Coating adhesion is strong, prolong the life of the coatin – the coating particles is seamlessly contact with object under the action of high pressure, the coating is more dense and the coating life is longer.

4. High utilization of paint – comparing to brushing, roller coating or air based spraying, airless spraying does not need to prepare paint at site so it avoids waste of paint; and the difference with traditional air spray is, airless

spray is to atomize paint rather than atomizing air, so it will not cause the paint to fly around and pollute the environment and cause waste.

Sprayer Selection

1. equipment performance- it’s mainlay about powder application rate with regarding to powder spraying machine, the processing ability of complex workpieces, its difficult to understand for the first time. The performance of similar products from different manufacturers often has a large gap.

2. the stability of equipment quality- industrial processing equipment working environment is very poor than home appliances and often work continuously for a long time without downtime, so the stability of the equipment is very important.

3. Technical service and after-sales service, many customers need the guidance of technical experts with rich production experience to be able to master the machine smoothly, and the general equipment sales clerk can not meet such requirements. They can only teach you how to use it.

Maintenance Guides

1. Spray line spray booth maintenance. If the air supply system of the spray booth is blocked or there is too much dust, the air filter should be replaced. About every three days, the paint filter system should be cleaned behind the spray booth, At the same time, it is necessary to clean the oil of the conveyor chain from time to time and lubricate it.

2. Maintenance of the paint supply system. After the spraying machine is used, open the paint return valve to have paint flow back to tank. Take out paint then add cleaning solvent into the mixing tank and start the pump. Open the return valve and spray the gun to the maximum rate to let the cleaning solvent in tube circulating and cleaning spray gun and pump. Pump and spray gun are extremely precise. Do not disassemble them when cleaning to avoid damage.

3. After one week or 50 hours of operation, the pump body, cylinder and sealer should be inspected carefully, the tightness of belt and sealing of pipe joint, the appearance of pump should be cleaned to maintain in good condition.

4. The main components such as clutch, return unloading valve, reducer and air compressor should be inspected regularly according to their requirements. If it is worn or damaged, it should be adjusted and replaced in time.