Water transfer printing or hydro printing, allow you to coat any printed pattern to object surface. You can use it to customize almost everything you can imagine such as car panel, phone cases and a whole lot more. Just about any material you can imagine can be dipped, including metal, fiberglass, wood, plastic, and glass. If you want it customized, hydrographics can help.

Water transfer printing or hydro printing, allow you to coat any printed pattern to object surface. You can use it to customize almost everything you can imagine such as car panel, phone cases and a whole lot more. Just about any material you can imagine can be dipped, including metal, fiberglass, wood, plastic, and glass. If you want it customized, hydrographics can help.

Our automatic water transfer printing line provides a drive unit to send out poly-vinyl film on water in a large dipping tank. Single axis reciprocator spray machine then spray a special chemical, known as the activator on the film when passing through. The film then turns into an ink that continues to float on the surface. Your object is then slowly dipped into the tank and ink, causing the pattern to be transferred to the object. Finally, a clear coat is applied to enhance and protect the finish. This coat can be matte, glossy, or satin, and helps to protect the finish from all sorts of damage. It’s about as durable as the clear coating used in automotive finishes.

Steps of WTP production:

- Preparation: This is a crucial step in ensuring good adhesion. Make sure the object is properly cleaned.

- Preparing film: Load the film correctly to drive device. A special blower will blow on film to make it smooth on water.

- Activate film: Spray machine will spray a chemical activator on the film that dissolves the film leaving the liquified pattern on the water surface.

- Transfer of pattern: Operators submerge the object through the liquified film. The pattern adheres to the prepared object.

- Rinse: Clean any leftover film residue and dry the object.

- Top coat: Spray a protective clear coat and dry in oven. It can be any material for varnish purpose such as UV, PU or others.

Machines for Automatic water transfer printing line:

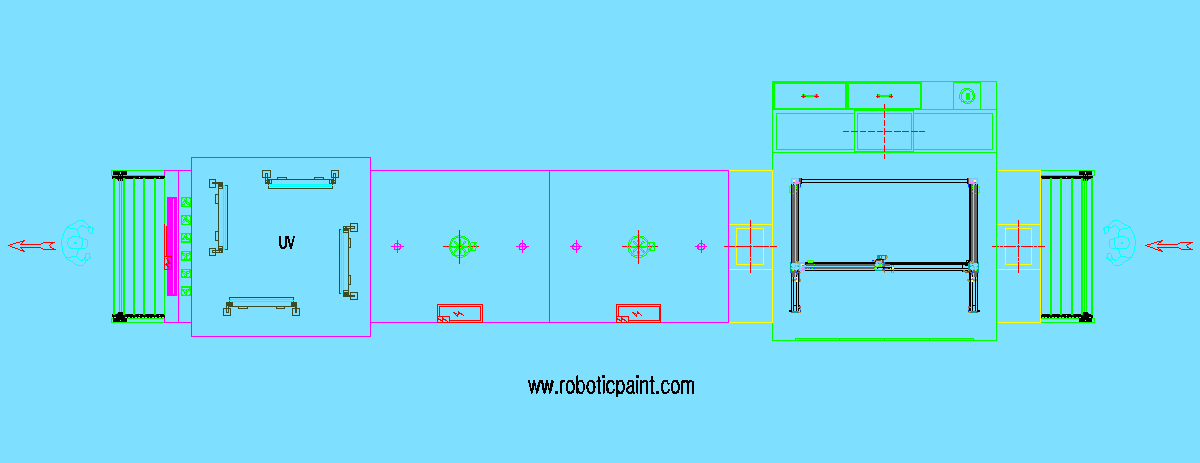

The printing line is composed by 3 major units: water trasnfer line, washing machine and dry oven.

The water transfer line includes film loading device, spray machine and a big water tank. Heating system is included in tank because the temperature must be controlled between 40-50℃ for best quality. If the temperature is too high, the pattern can be easily destroyed, and if temperature is too low, the pattern can not be activated properly.

Washing machine provides proper water pressure control to make sure object is properly cleaned and no damage to patterns.

Dry oven can be box type or tunnel type depends output requirement.

Water transfer printing line installation view

In need of our Water Transfer Painting Machine?

Find more about our machine construction details or send us your enquiry now to find out what we can do for you!