Headquarter in Shenzhen China with branches in multiple province, Robotic Paint Group is specialized in offering spray painting machine and painting robot solutions to automate your painting lines.

We have a smart engineering team to design out the best painting machine upon customer requirements. With seamless cooperation with world class robot components suppliers such as ABB, Mitsubishi, YASKAWA, Panasonic, THK, HIWIN, Schneider, Siemens and FESTO etc, we’re simply offering the best robotic machines to support your very strict needs. Our oldest spray painting machine is still working problem free since 10 years before!

We represent the industry leader in automatic spraying machinery. We have multiple workshops for precise production over different machinery parts. Based such hardware facilities, we are able to demonstrate to our customers in real terms the capabilities of our proposed solutions. For worry free purchase, we have sample painting service for all our machines. By this way, customer will be confident over machine functionality and performance.

We offer prompt, friendly customer service with knowledgeable, well-trained representatives available to answer each your questions. We have an extensive inventory of thousands of replacement spare parts and accessories. Our service technicians are some of the best in the Industry. They are capable of overseeing installation, start up and training on systems.

We will continue to sell and service quality products at a fair price with superior support that keeps our customer relationship strong.

Our Product & Service

5 Axis Painting Machine

The most popular model to fulfill with a big range products painting requirement. Our 5 axis spray paint machine provides two structures – 2 & 4 support trays to meet with your different production requirements.

6 Axis Painting Robot

6 axis painting robot is very flexible robotic design. With all available functions from 5 axis painting machine, 6 axis robot can be programmed to spray on very complex shaped products easily via control panel.

Custom Design

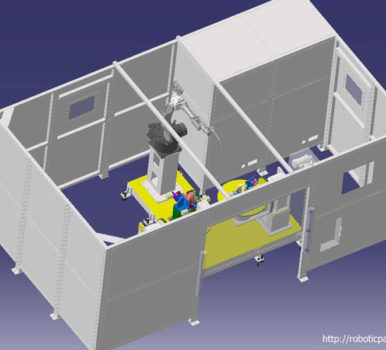

We offer deeply custom design service to meet with client side production needs. This includes custom machine size, choice of components & integration with existing paint shop etc. Just send us your requirements!

Machine Show Case

Industrial Application

Hardware Products

For hardware spray painting such as nonstick cookware, car parts and houseware etc.

Plastic Products

Plastic products spray painting such as phone case, switches, mirror and laptop covers etc.

Woodware Products

For various woodware products spray painting such as gift box, wooden door and board etc.

Electronics Products

For electronics products such as circuit board, clocks, watches, lamp cover & camera etc.

Our spray painting machine & painting robot is widely applied in a big range industries for surface treatment such as car parts, houseware parts, plastic & hardware parts etc. High quality and non-stop continuous operation makes our machine extremely outstanding for man power saving. Factories do not have to worry anymore about hiring a professional for paint job at high costs, just common workers be able to operate our machine properly for high quality production!

Machine Advantages

Man Power Saving

Machine can be 24*7 continous working at high speed, 3 times more efficient comparing to manual operation.

Cost Saving

Less workers required, less bad products wasted, three times more production capacity at low costs!

Improved Quality

One time configuration then always doing the same high quality spraying by machine. Stable & reliable!

We simply choose the best of the best robot components for spray painting machine construction. Crucial parts like servo packs, moving guides and PLC control systems are all top brands such as Siemens, Mitsubishi, THK, Omron etc. We have very reliable and trustable supplier chain to program the best robots by client requirements.

Service Flow Chart

Design by Client Requirements

Upon mutual understanding, we make CAD design according to client side specific requirements

Production

Upon drawing confirmation, we do manufacturing in workshop and make full test before delivery.

Training Plan

Before delivery, we provide necessary training service to client engineer. This includes a manual book and technical skill course.

Warranty

All our machines provides at least 12 months warranty since the date of production in client factory. We offer component replacement for free if run into problem.

Tech Support

All our machines are life time tech supported, its only referring to machine itself but general integration with customer production line based our years experience.

Call Back

We do periodical call back service to track machine performance, especially at some crucial time points such as maintenance program starts. We’re your powerful backend!

Factory Quick View

We manage the entire flow chart for automatic spray painting machine and painting robot production. Each stage is handled professionally by engineers in charge. Either from source material treatment or software programming, we can easily track though management system.

Based our 5000㎡ production workshop and millions worth spare parts warehouse, we are capable of offering high quality solutions at the earliest upon customer needs.

All our painting robots are fully tested in house before delivery, a single small issue will be tracked at the very first before reaching to customer. Trust with us means trust to success!

Honor Customer