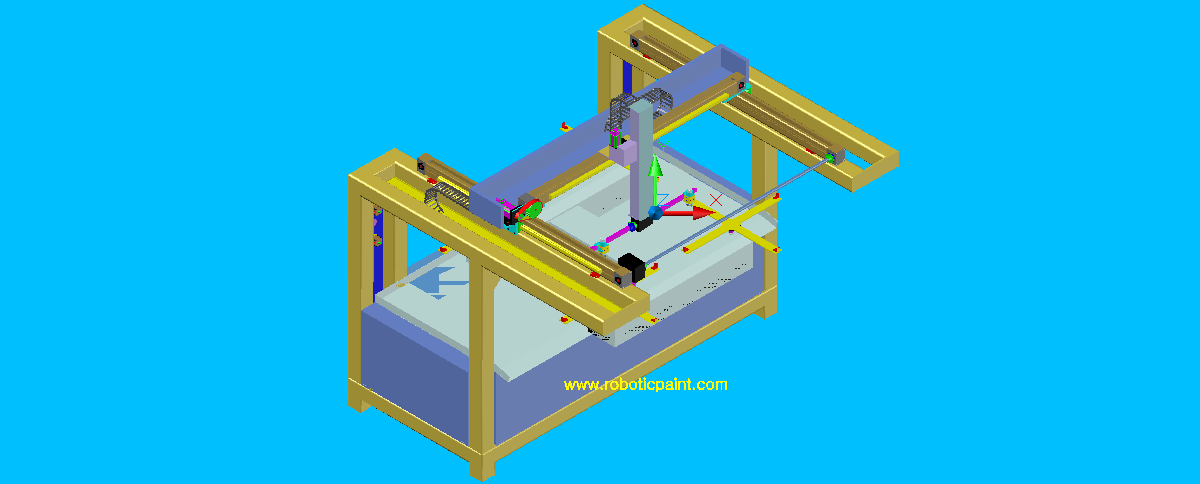

5 axis spray painting machine quick view

5 axis spray painting machine quick view

Our five axis painting machine is a flexible device be able to spray over different objects. With programmable PLC control of servo motors, machine can be accurately positioned and programmed to work with numorous painting requirements. Further more, it works with different spray guns and can be installed in different ways upon requirement.

5 axis spray painting machine is a popular robotic setup for smart spray in different angles on object. The machine can work 24*7 continuously to meet with heavy production requirement. Under a single programming, product can always get the same smooth and high quality finishing and reduce operation costs greatly. The machine is deeply optimized for power saving and maintenance requirement.

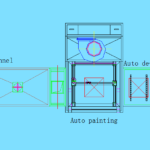

5 axis spray painting machine diagrams

| Item | Details |

| X-axis (left-right) |

|

| Y-axis (back-front) |

|

| Z-axis (up-down) |

|

| W-axis (gun-rotate) | Use step forwarding motor, simple structure with long life cycle. Motor is installed on top to completely avoid waste paint pollution on motor surface;

|

| T-axis (self-rotate) |

|

| Position exchange | The turntable for position exchange between spraying and loading. Ensures spray gun continous working and reduce idle state as much as possible;

|

| Digital control/config | One set spray gun with more than 10 operation states, be able to store 200 different products’ programming; Touch screen is 7-inch color screen. PLC is OMRON series. |

| Programming | Our company has professional software engineers to program for different products with accurate process control. For example programming for single, two, three or five sides continous painting. |

5 Axis spray painting machine FAQ

5 Axis spray painting machine FAQ

Q: What’s the available choice of machine setup?

A: 5 axis spray painting machine can be setup for offline dedicated unit (like above photo) or setup for online detection. The difference is there’s no base platform for online machine and it’s working together with your conveyor. Generally speaking, the programming is more complex than offline machine.

Q: What brand PLC/Servo motor being used?

A: We select Omron PLC and Yaskawa/Panasonic servo pack and motors as default configuration. We can also use specific brand upon client requirement.

Q: How do I know how many axis will I need?

A: Just show us your product and our professionals will learn and suggest the best solution.

Q: Do I need your engineer for installation?

A: It depends, mostly you will need our engineer for online machine installation. But in some cases, we also need to send engineers for offline machine programming. Especially when you have a big team to operate our machines.

Q: Do I get discout for large order?

A: Yes, large order means we can get lower price for material purchasing. Thus our clients are deserved a better quotation.

Q: Why our machine is outstanding?

A: We never compete by super low price to win your order. Since from our business start, we have strict quality control from raw material selection and full machine structures. We’re building our reputation as top supplier in robotic industry.

In need of our Five Axis Spraying Machine?

Find more about our machine construction details or send us your enquiry now to find out what we can do for you!

Hello,

We are a fiber boat manufacturer in turkey,

We need a spray robot for our gel coating and painting applications.

Our largest size is 8m x 20 m wide.

Could you give us an offer for your selected products.

Best Regards,