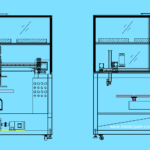

6 Axis Spray Paint Booth is advanced setup of a stand alone six axis painting machine. It’s a full functional painting unit with a paint booth included plus a smart robot controller. It’s widely compatible with a variety of painting objects within design capacity. In order to avoid any mistake, our robot controller provides a step by step simulation before we put the program in live painting production. And, this painting machine can be deeply custom desgin to meet with client side specific spraying requirements such as the product size, space limit and other mechanical or electric special etc.

6 Axis Spray Paint Booth is advanced setup of a stand alone six axis painting machine. It’s a full functional painting unit with a paint booth included plus a smart robot controller. It’s widely compatible with a variety of painting objects within design capacity. In order to avoid any mistake, our robot controller provides a step by step simulation before we put the program in live painting production. And, this painting machine can be deeply custom desgin to meet with client side specific spraying requirements such as the product size, space limit and other mechanical or electric special etc.

6 Axis Spray Paint Booth Quick View

| Dimensions | L2000 x W1800 x H2000 mm(can be customized) | |

| NO. of support tray | 2PCS | |

| Support tray transfer | By rotation or moving table | |

| Servo motor | Panasonic /Mitsubishi /Yaskawa | |

| Mechanical motor | CPG | CPG |

| Man machine interface | LNC robot pad (dedicated for spray painting design) | colored |

| Spray gun moving stroke | X: ±1000 mm Y: ±600 mm Z: ±200 mm Spray gun rotationh: 0~180° |

6 axis |

| Spray gun | IWATA, Devilbiss | 1PCS |

| Paint pump | Graco/Prona | 1 |

| Moving guide | THK | |

| Spray booth material | SUS304 stainless steel | 1 |

| Filter type | Water curtain vortex type | |

| Exhausting | Centrifugal blower with air pipe | |

| Air flow stabilizer | FFU from ceiling installation | |

- Moving guide: THK linear guide modular with special aluminum guide

- Main structure: T2.0 & T1.5 stainless steel plates and square pipes welding

- Motor: Panasonic or Mitsubishi servo motors

- Program: Robot motion controller

- Man-machine interface: LNC touch pad

Operation: touch pad programming.

Painting machine is constructed inside spray booth with central control. There’re foot cups and wheels for easy transfer to desired location. Being a flexible spraying device, it’s widely compatible with a variety of products painting requirements for easy programming. It can be easily connected with before and after production facilities. The outstanding design and powerful servo system make it capable of continuous working by extra high efficiency.

6 Axis Spray Paint Booth FAQ

Q: What’s the difference with a 6 axis painting machine or robot?

A: The basic difference its fully integrated with spray booth and programmed together. Mechanical structures are seamlessly fixed by screws and welding technique. Depends the specific production requirement, this booth and machine can be deeply custom design.

When referring to a robot arm, they have different working principles and used under different conditions. They have the same control system though.

Q: How do I connect spray booth with my AHU?

A: We can have FFU for fresh air supply at the booth ceiling. Thus you don’t have to connect extra device.

Q: How do I clean out waste paint?

A: There’s waste tank behind for cleaning purpose. We just open the lid and clean up and replace water regularly to make the spray booth working well. Be sure to have a good maintenance plan to avoid any blockage of the pipe system.

Q: How much space do I need to install this machine?

A: Machine dimensions are L2000 x W1800 x H2000 mm. You need half bigger space area at least to make it working properly.

Q: Is there any additional item to make the spray booth working?

A: You will need stable compressed air supply and water supply(if it’s water curtain setup).

Q: What’s the required electricity of this machine?

A: 220-380V /50Hz single phase electricity is required to power on this machine.

Interested in our spray booth?

Find more about our painting machine construction details or send us your enquiry now to find out what we can do for you!