Chain Conveyor Troubleshooting for Automatic Loading System

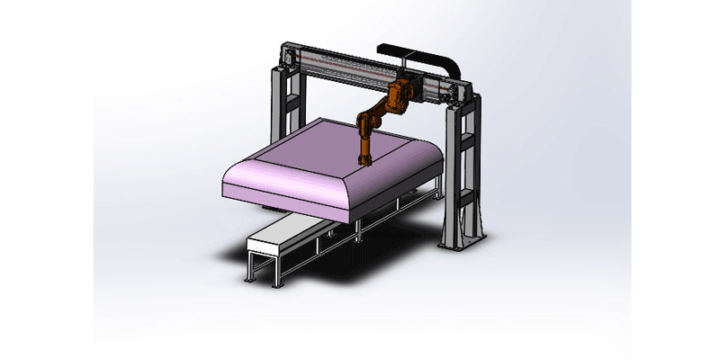

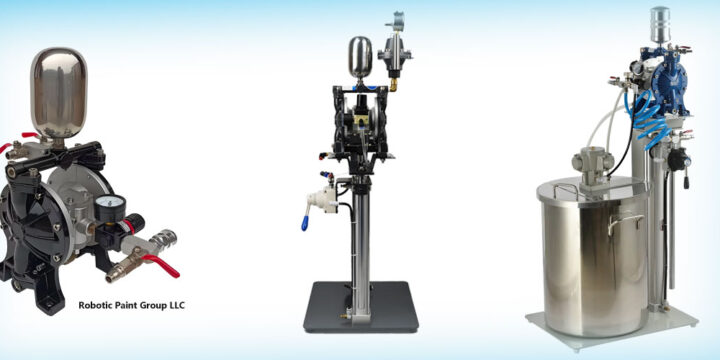

We have developped an automatic loading machine for vacuum metallization painting line system considerring its great improvement to reduce labor works. When it's well programmed and everything well tested for live production, suddenly some day we found the automatic loader can not put objects properly to chain spindle. After inspection on each unit carefully we finally found its due to the chain pitch elongated during operation. Technically speaking, the painting line system is a high precision setup which should be always accurate in mechanical structure. Among all the components, conveyor chain is the most crutial part as it will carry all spindles and products to pass through various treatment stations. Elongated chains in painting lines will directly trigger a series of cascading failures in terms of machinery, processes, and safety.…