Flame Treatment or Annealing Before Plastic Painting

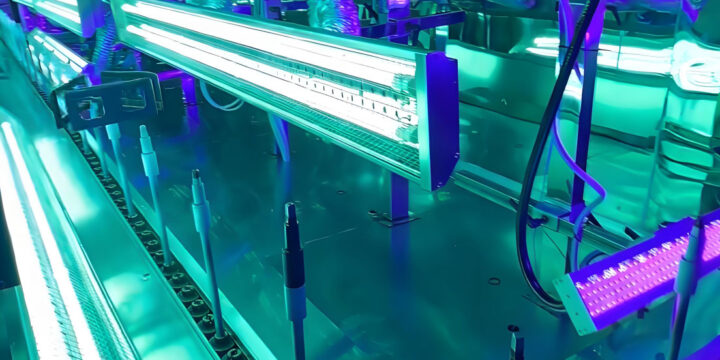

In order to receive the needed surface finishing, plastic products need various pretreatment including cleaning, heating and blasting etc. Flame treatment is a popular solution in many plastic painting lines. However it's not the solely choice according to the exact plastic components. In this article we'll briefly introduce the pros and cons of flame treatment and another solution called annealing. What is Flame Treatment? Flame treatment is a surface treatment technique performed on plastics before painting. It uses flame to briefly heat the plastic surface at high temperatures to improve wettability and adhesion. This treatment effectively removes oil, release agents, and other impurities from the plastic surface, while also increasing the surface's polarity, thereby improving paint adhesion. Principles of Flame Treatment Flame treatment uses a high-temperature flame to transfer energy…