Common Surface Treatment Solutions for Metal Parts

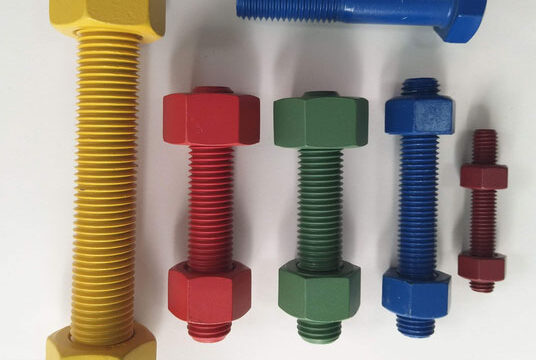

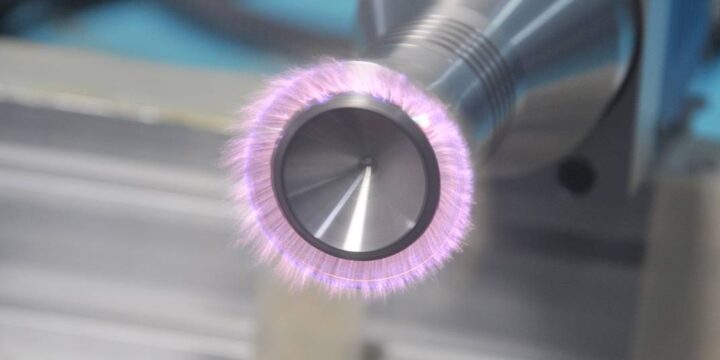

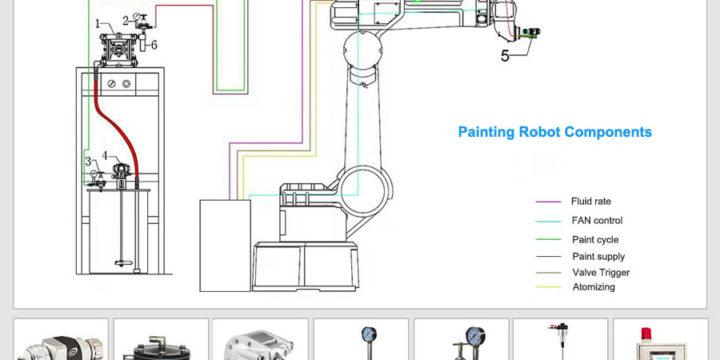

Any metal production will need a form of surface treatment before arrived to user side. A bare metal will easily be oxidized or rusted if no proper surface treatment applied. We collected a list of common solutions for metal parts surface treatment for quick view. 1. Electroplating: Commonly used metal parts are electroplated with zinc, nickel, chromium, copper, etc., which has the functions of anti-corrosion, improving wear resistance, and enhancing aesthetics, etc. 2. Anodizing: Commonly used for aluminum alloy surface treatment, it is an essential process 3. Blackening treatment: can maintain the dimensional accuracy of parts, anti-corrosion and beautiful appearance 4. Spray painting: mainly for corrosion protection of exterior parts, such as racks, etc. 5. Polishing: Polishing refers to a processing method that uses mechanical, chemical or electrochemical effects to…