Introduction and Knowledge of Coatings for Spraying

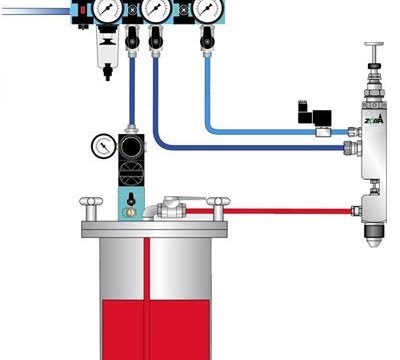

Overview of coatings Coatings are complex chemical mixtures. Generally speaking, coatings are mainly composed of primary, secondary and auxiliary film-forming substances. The main film-forming material is an indispensable part of the coating, which plays a leading role in the performance characteristics of the coating layer. Secondary film-forming substances refer to various pigments, fillers, which cannot be filmed alone, but are important components that make up the layer and affect their properties. Anancillary film formers include solvents and many other additives that improve the properties of coatings and coatings. Classification of paints According to the state of the coating: powder coating and liquid coating; According to gloss: glossy paint, flat paint and matte paint; According to the drying method: self-drying paint, baking paint, infrared drying paint and ultraviolet drying paint (i.e.,…