Photo Catalyst Paint Application

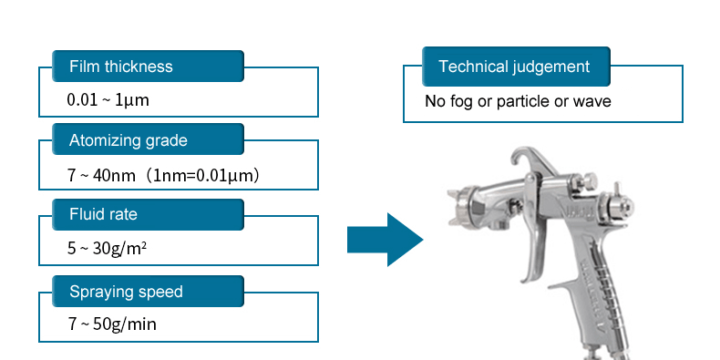

Photo-catalyst paint or known as self cleaning paint is a special coating on building glass or ceramic production. This coating can create a super-hydrophilic glass surface, lubricate the glass when it rains, and take away contaminants such as dust through the sliding of the water film, it also has anti-fog and antibacterial effects. Once the glass or ceramic is painted by this type coating, there is no need for regular cleaning by workers. The photo-catalyst coating is great in performance but it's not easy to apply well on glass. We need either a professional technician or use a pre-programmed robot to spray properly for mass production purpose. Following is the coating spraying requirements To spray photo-catalyst coating perfectly under mass production, it's normally by conveyorised automatic painting system. One set…