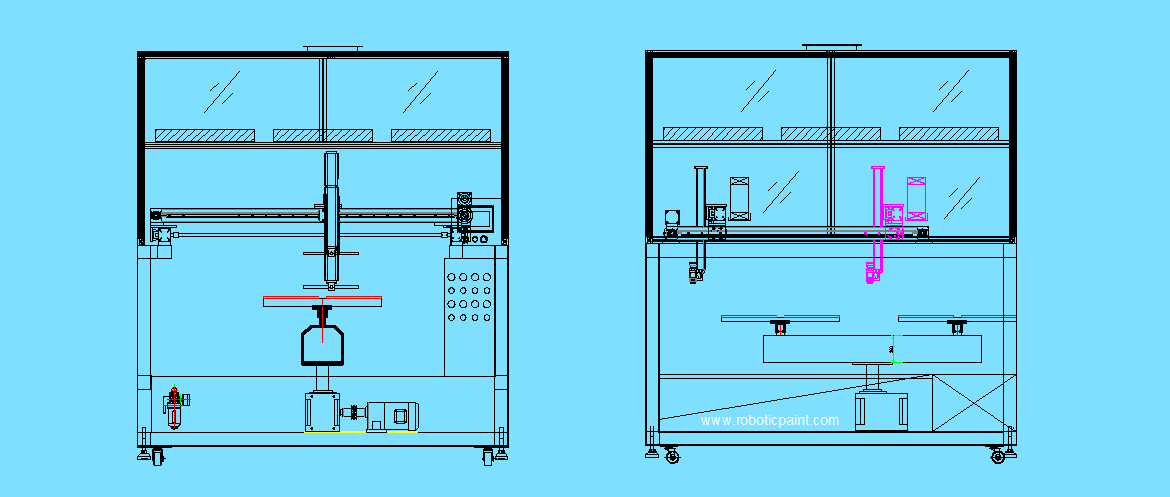

This Five Axis Spray Booth is advanced setup of our five axis painting machine. It’s designed together within spray booth as a full functional painting unit. Customer no need to buy spray booth separately then make extra installation. Everything is pre-setup and ready to use for production purpose. Five axis painting machine can be custom desgin like all other models then fit into this spray booth. Painting machine and booth control are in same panel so it’s greatly simplified system for easier and more convenient operation!

This Five Axis Spray Booth is advanced setup of our five axis painting machine. It’s designed together within spray booth as a full functional painting unit. Customer no need to buy spray booth separately then make extra installation. Everything is pre-setup and ready to use for production purpose. Five axis painting machine can be custom desgin like all other models then fit into this spray booth. Painting machine and booth control are in same panel so it’s greatly simplified system for easier and more convenient operation!

Five Axis Spray Coating Booth Data

| Dimensions | L2300 x W2200 x H2400 mm(can be customized) | |

| NO. of support tray | 2PCS | |

| Support tray transfer | By rotation or moving table | |

| Servo motor | Panasonic /Mitsubishi /Yaskawa | |

| Mechanical motor | CPG | CPG |

| Man machine interface | 7″ Weinview 16 million resolution touch screen | colored |

| Spray gun moving stroke | X: ±1500 mm Y: ±860 mm Z: ±300 mm Spray gun rotationh: 0~180° |

Five axis |

| Spray gun | Roxgen, Devilbiss | 2PCS |

| Paint pump | Graco/Prona | 1 |

| Moving guide | THK | |

| Spray booth material | Stainless steel | 1 |

| Filter type | Dry filter or water curtain optional | |

| Exhausting | Centrifugal or axis flow blower | |

| Air flow stabilizer | FFU or connect with existing AHU unit | |

- Painting machine moving guide: THK linear guide with special aluminum guide

- Main structure: T2.0 & T1.5 stainless steel plates and square pipes welding

- Motor: all motions control powered by Panasonic or Mitsubishi servo motors

- Program software: German Siemens program controller and OMRON PLC

- Man-machine interface: Weinview 16 milliion high resolution touch screen

Operation: central control of full unit on single panel. One time setup then continuous working, less maintenance guaranteed.

Painting machine and spray booth are seamlessly connected for easy transfer and positioning. Foot cup and wheels are in place to reduce labor efforts when moving to desired space. Machine can be easily connected with factory current production facilities and no special training required. After initial setup, regular people be able to operate so you don’t have to hire a professional painter anymore which is quite cost effective choice.

Five axis spray booth applications:

Besides integration with a spray booth and other necessary components, this five axis spray booth has no functional difference than traditional setup. Thus its widely compatible with various products paint spraying requirements. Depends customer side specific painting and installation requirements, spray booth can be deeply custom setup to make sure it will be 100% fit in customer paint shop.

Five Axis Spray Booth FAQ

Q: What’s the difference with standard 5 axis painting machine?

A: The main difference its fully integrated with spray booth and programmed together. Mechanical structures are seamlessly fixed by screws and welding technique. Depends the specific production requirement, this booth and machine can be deeply custom design.

Q: How do I connect spray booth with my AHU?

A: You need to confirm us your current airpipe specifications so we can leave a compatible window on booth system. We can also make FFU directly and you only need to handle air exhausting.

Q: How do I clean out waste paint?

A: The spray booth provides all functionalities from a standard setup. We can make it water curtain or dry filters for waste paint collection. For water curtain option, there’s waste tank behind for cleaning purpose. For dry filter solution, we just replace it regularly.

Q: How much space do I need to install this machine?

A: Machine dimensions are L2300 x W2200 x H2400 mm. You need half bigger space area at least to make it working properly.

Q: Is there any additional item to make the spray booth working?

A: You will need stable compressed air supply and water supply(if it’s water curtain setup).

Q: What’s the required electricity of this machine?

A: 220-380V /50Hz single phase electricity is required to power on this machine.

Interested in our Five axis spray booth?

Find more about our painting machine construction details or send us your enquiry now to find out what we can do for you!