Automatic Spray Painting Machine for Guitar

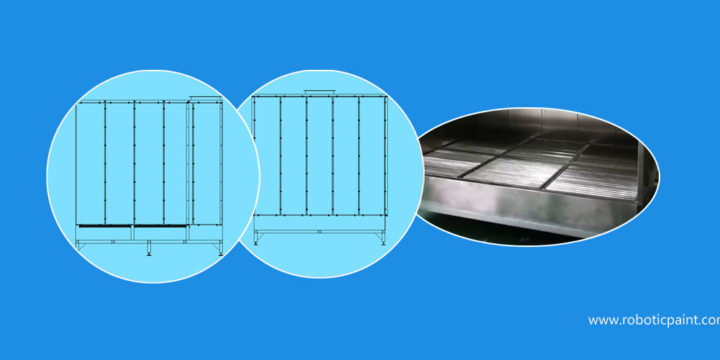

[vc_row][vc_column][vc_column_text css=""]Automatic spray painting machine for guitar is easy to operate, no need skilled technician, worker be able to familiar with program setup by just few clicks away. Improve production efficiency, save labor and also environment friendly by continuous operation. It's widely compatible with lots of product spraying requirements with a touch pad control. Advantages of Painting Machine This small size painting machine is simple robotic operation on touch screen, almost no training required but just few basic logic understanding to get started. Central operation Reliable mechanical structure Easy installation and fix Durable and flexible Programmable for numorous objects spraying Less maintenance guarantee! Painting machine construction details as following: Model GY260 Dimensions L2600*W2250*H2200mm(can be requested) Reach limit 500MM*1000MM*700MM(X*Y*Z) Spraying size 500*700mm Electric voltage 220V ±10 50Hz Air pressure 0.6Mpa Weight…