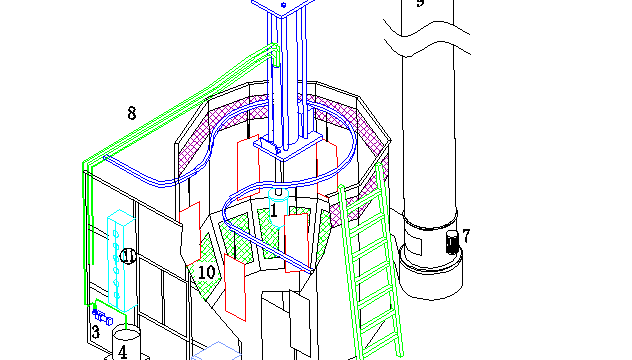

Electrostatic DISK Spray Paint Booth

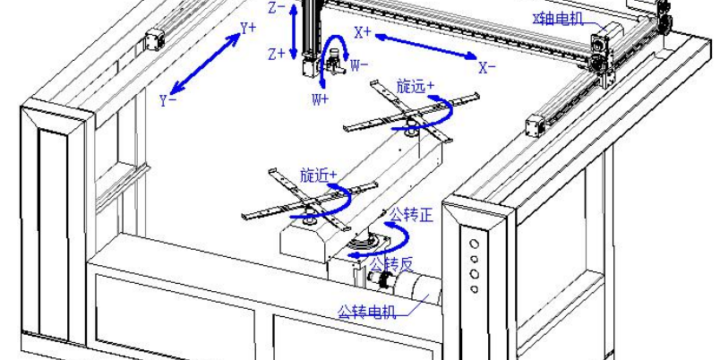

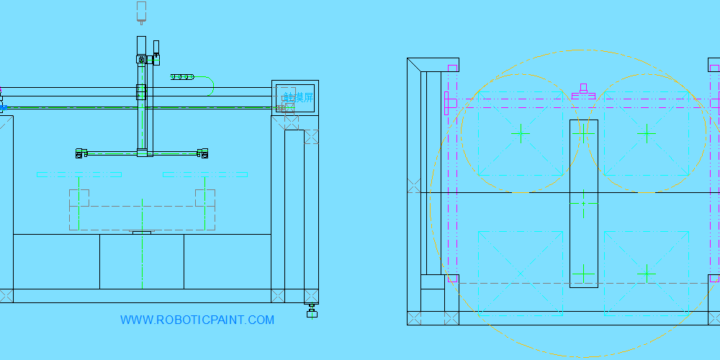

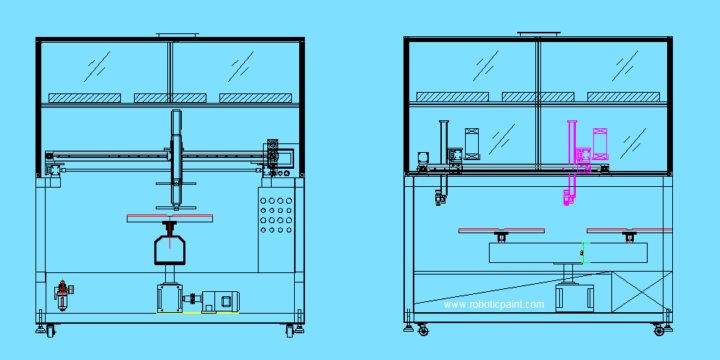

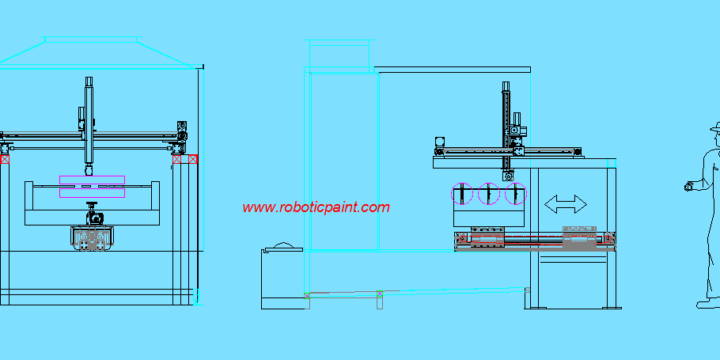

Electrostatic DISK spray paint booth is an advanced setup in coating industry. Either for it's spray gun and booth design or the special conveyor layout, it's different than any other painting system. Because of its unique advantages, Electrostatic DISK spray paint booth is widely used for those complex shaped objects high quality painting system. In this article we'll introduce each unit step by step with our actual application experience. Electrostatic DISK spray booth quick view 2—3 higher efficiency when working with painting line smooth and high density paint spraying, greatly reduced manual spray work simple operation, no special training required for quick application inverter control of gear paint pump, stable paint supply with accurate flow control PLC control of reciprocator motion, speed adjustable with 6 stations to work with different…