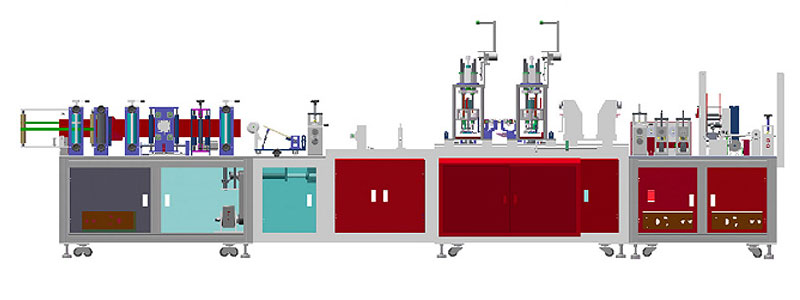

N95 /FFP2 mask making machine is full automatic production line setup including: fabric loading machine, pattern forming machine, nose wire inserting, pad printing, folding and welding, ear band welding and cutting. Each stage is functional by robotic programming and continuous operation. One minute capacity under production mode 35-45 pieces. This N95 /FFP2 mask making machine can work with up to 6 layers fabrics mask production. Only one time setup then everything will be working under automatic mode. Worker only need to handle final packing and waste material collection.

N95 /FFP2 mask production production flow: multi-layer non-woven fabric rolls are subjected to compound roll welding after feeding. Nose wire is welded automatically after unrolling and cutting. Two rolls of ear band are welded after automatically unrolling and cutting to designated length. Then masks are folded in half. After ultrasonic welding and fusion, the masks are rolling-cut and formed. Finally, we get finished mask.

N95 /FFP2 Mask Making Machine Features

- Full automatic production line mode, flexible structure to attach with other workstation.

- PLC central control for each unit functionality, each machine is working simultaneously by preset programming.

- Automatic working from fabric loading – mask forming – nose wire inserting – earloop feeding & welding to final face mask.

Face Mask Making Machine Technical Data

| Dimensions | L9660*1060*2120MM | |

| Total weight | Approx 1400KG | |

| Electricity | 220V/50Hz (11KW) | |

| Capacity | 35-45pcs/min | |

| Air pressure | 6KG/CM² | water & oil free |

| Folding Symmetry | ±1MM | |

| Operation requirement | Temperature 5 ~ 35 ºC, humidity 40-80% HR | Datasheet download |

Machine is developed using state-of-the-art high technology and only available as single geniune copy. It is designed to meet with high speed production at superb reliability. Only one time setup and everything will be handled automatically by preset programming.

Each stage of this mask production line is flexible and scalable to work with other units independantely. Under production mode, line capacity can be is 40-60 pcs/minute, daily output can reach 50,000-80,000pcs. Machine investment can be earned back within one week then every extra piece will be pure profit!

Machine can be loaded with different moulds design to work with different specifications of masks production. 1-6 layers non-woven mask fabrics can be worked upon requirements. Each unit is precise CNC machining with maximum accuracy. Alloy aluminum profiles and stainless steel structures provide excellent appearance and durable performance for continuous operation.

Face Mask Making Machine Main components

- Fabric loader: Servo drived handler with tension control

- Main structure: 50*50*2T aluminum profiles and stainless steel rollers according to specific design.

- Motor: all motions control powered by programmable servo motors.

- Mould: CNC machining for N95 /FFP2 pattern

- Forming: Ultrasonic welding

Production technique: Modularized production for each component with minimum tolorance control. Each station is well programmed to work simultaneously.

After service: All machine is life time tech supported. Our engineers have plenty experience in live production lines and always ready to provide you quick solution 24*7 either for mechanical or electric or software level requirements.

N95 FFP2 Mask Making Machine FAQs

Q: What’s the lead time of this N95 mask making machine?

A: This mask machine is our newly developped model, roughly production time in factory 12-15 days upon payment confirmation.

Q: Does it fully compatible with N95 FFP2 mask standards?

A: Yes, it’s specially designed for N95 and FFP2 mask production.

Q: Is there any documentation of installation and maintenance?

A: Yes there is. We will provide all necessary documentation and even onsite installation service. Details to be discussed upon machine order.

Q: What kind electricity supply do I need?

A: Machine works with 220V 50Hz electricity supply. If you have other type voltages, a small transformer will be required.

Q: Is there any warranty?

A: We provide 12 months warranty since the date of production in customer factory.

Q: What is the needed material for mask production?

A: You will need non woven fabric, melt blown fabric, earloop wire and nose wire. Up to 6 layers workable

Interested in our N95 FFP2 Mask Making Machine?

Contact us for more about technical details or download this mask making machine datasheet!