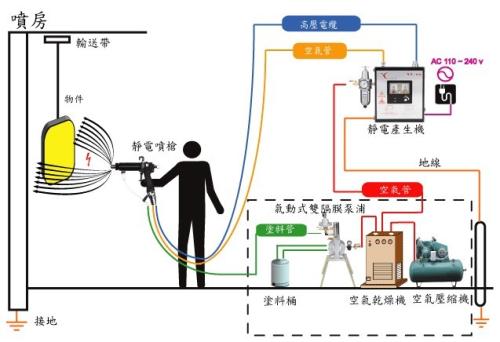

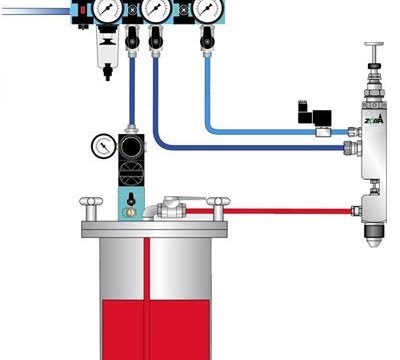

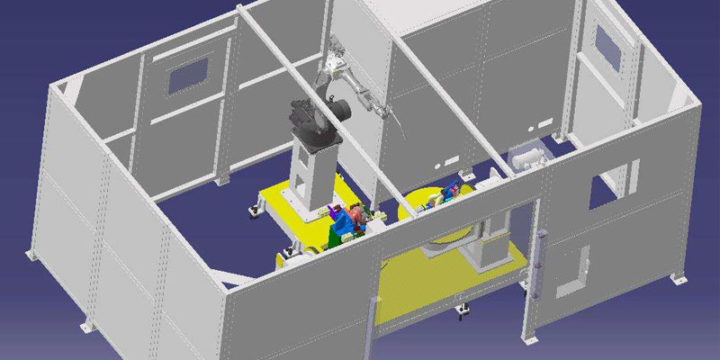

Pneumatic Diaphragm Pump & Paint Mixer

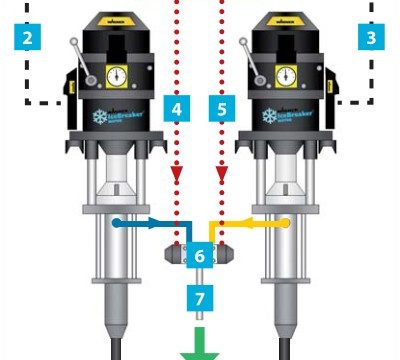

Pneumatic diaphragm pump is a volumetric pump that is driven by a compressed air source and enters through the air inlet and reciprocally deforms through the diaphragm in the diaphragm pump chamber. The working principle of pneumatic diaphragm pump is similar to reciprocating pump. For a long time after the appearance of pneumatic diaphragm pump, there are many inappropriate ways of using it safely and correctly. We have summarized some of problems we have encountered so far for basic guides to operators. Pay attention to the following when using pneumatic diaphragm pump: 1. Ensure the biggest particles contained in liquid do not exceed the pump maximum safe passage diameter. 2. The intake pressure should not exceed pneumatic diaphragm pump maximum allowable operating pressure. Excessive pressure of compressed air can cause…