Either we work with manual or automatic paint spraying, paint booth is a must equipment to be used. Either for environment consideration or to improve the painting quality, a well constructed paint booth is necessary for all kinds paint shop. There’re two types paint booth in use – dry filter and water curtain. They both are widely used in vrious industries. But which one is better to power your paint shop? We’ll introduce in details so you can make a smart choice.

Dry Filter Paint Booth

Known as paper filter paint booth. With the rapid development of painting industry, dry filter paint booth is well recognized by the market and becomes the best choice for environment friendly consideration. Dry filter paint booth uses a combination of fiber filter and a paper filter to achieve up to 98% filtration effect. It is easy to disassemble and easy to replace and maintain. The paper filter consists of two layers of holes and foldable cardboard. They are combined to form a V-shaped over-rate chamber; the paper filter can be replaced/non-adhered with a long service life.

Working principle

Dry filter holes arrangement produces a venturi or cyclone effect, forcing the paint particles to land at the bottom of the filter chamber, and the air flow is discharged from holes. The high efficiency of this separation comes from this Venturi effect. The separation rate reached 96% depending the nature of paint properties. Even for high viscocity and sticky paint, the filter is rarely blocked. Fiber filter can blocks every tiny particle.

Construction material

Dry filter paint booth materials available: cold rolled sheets, galvanized sheets, stainless steel.

Dry Filter Paint Booth Structure

- Booth support base is formed by square pipes welding, upside tank chamber provides an isolated working space, booth front side provides a stable air flow and top side provides an air exhausting device;

- Paint booth air exhausting device has a bellows housing mounted above booth chamber, exhausting device is handled with an air suction port and an air outlet, and the air suction port is connected with the air outlet of the machine base;

- Booth motor fan is installed outside booth chamber to drive the fan and the air is sucked from the air suction port then discharged through outlet nozzle;

- Dry filter layer, has a plurality of filter plates, longitudinally installed at the air inlet portion of the front side of the inner space of the machine base to form the first filter layer; the second filter layer has a plurality of filter plates, with the opening facing upwards The V-shaped arrangement is respectively mounted on the upper front and rear portions of the inner space;

- Blocking device has a plurality of partitions, respectively surrounding a predetermined portion around the outside of the air inlet to form a painting space;

Water Curtain Booth

The water curtain booth is to catch wasted paint in water tank or water curtain surface, the odor generated during painting and tiny amount of non-adsorbed paint particles are filtered through the multi-layer water curtain then discharged through exhaust fan. Outside the spray booth, it can purify the working environment and protect operator health, and can furthermore enhance the product surface finishing.

Working principle

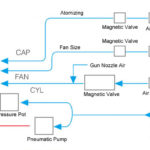

Water curtain booth (paint booth) is by the self-priming pump to the water curtain plate, waste gas (paint fog) sprayed from gun is catched by water curtain then flow into the tank below. A tiny amount of paint fog is discharged to workshop outside by the upper fan. No waste air will stay in workshop to give workers a good working environment.

Use and maintenance

It’s suggested use butter on the fan blades before water curtain booth put into production, which will help you to clean waste paint on the fan.

It is necessary to ensure that the fan is rotating forward when starting up, so that the exhaust gas in water booth can be discharged outside workshop. If it is reversed, rectify the cable connection from motor.

The fan should be cleaned regularly for waste paint on the blade every few periods of time. Be careful not to change the blade during processing, which will make the blade rotate unevenly and reduce the life time. The water in tank can’t be over 2/3, which makes it easy to block pump. The pump can’t be running without water. If water can’t be pumped, please cut off the power immediately.

Dry filter vs Water curtain

As we see above, dry filter paint booth is mainly powered by replaceable fiber filter which is affordable and easy to install. Water curtain booth is by water cycling to collect waste paint in water tank.

When dry filter needs to replace, we just take out directly then install with new piece. Old filter can be treated easily with minimum environment pollution. For water booth side, we must take out solid type waste paint regularly and abserve the viscocity in water tank to avoid stuck of water pipe. When change with new water, the waste water must be well treated by certified company as it’s quite dangerous.

Let’s say we replace dry filter or water every week, the cost of dry filter approx USD50 and waste water treatment charge approx $50/ton. Normally a paint booth water supply should not be less than 1.5T so the treatment cost will be $75.

Another concerned point is about booth cleaning. Dry filter booth cleaning is very limited as over 90% wastes are sticky with filter. We just need to take out waste filter then put with new. But for water based booth, we must take out solid wastes regularly from water tank and scrap the chamber inside properly to maintain a clean evnironment.

So based all above points, we highly suggest dry filter paint booth either for ease of use or potential cost in production.