In plastic painting line system, flame(or flamming) treatment is a popular setup to meet with high end painting requirements over different plastic materials. Especially for PP plastic, flamming is a must process for guaranteed contact to coating film. In this article we will introduce why it’s important and how it works.

Flame treatment refers to the process of oxidizing plastic surface with a strong oxidizing flame. It is mainly used to improve the painting characteristics and adhesive characteristics of polyolefin plastics. The technique is to increase surface activity and increase the primer adhesion to workpiece surface.

Definition

In order to facilitate the foaming compounding process, plastic surface tension value must meet the production requirements, surface tension value is generally required to reach about 41 dyne. However, polypropylene material surface tension value itself is only 31 dyne, which is far from meeting the production requirements. Flame treatment technology can change its surface tension to reach about 48 dyne.

Principle

Flame treatment is a process widely used for surface modification of substrates such as plastics, glass and metal foils etc to improve their adhesion to liquid agent like coating and ink. We generally use surface tension or surface energy to measure substrate ability of liquid absorbtion. If substrate surface energy is at high level, the liquid will become more wet on its surface and have good ductility. Making the liquid more wet on the substrate is basis for the substrate to adsorb liquid.

If the liquid is spherical on substrate surface, it indicates the surface tension of substrate is lower than liquid and wettability is poor. If the liquid forms a large uniform liquid film on substrate surface, it indicates substrate surface tension is greater and has better wettability. Flame treatment can increase the substrate surface tension to make it easier to print, spray and adhere. Flame treatment involves a series of complex physical and chemical reactions.

Physical principle of flame treatment is that high-temperature flame transfers energy to oil stains and impurities on substrate surface which causes it to evaporate when heated so it plays a cleaning role.

Chemical principle of flame treatment is that flame contains a large number of ions and has strong oxidizing properties. At high temperature, an oxidation reaction occurs on object surface, a layer of charged polar functional groups is formed on object surface. It will increase its surface energy and its ability to adsorb liquids.

In actual condition, flame temperature, the distance between flame and object and treatment time are important factors affecting the treatment effect.

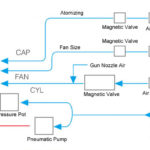

Robotic operation

A popular method for flame treatment handling is by robot with a flame spray nozzle. The manipulator moves on the surface according to preset program, flame is covered on the plastic surface by same distance and working state. The robot movement must ensure that all surfaces are covered and must be no repetition. Because repeated burning will destroy the hydrophilic components generated on plastic surface, and over-burning will occur. The processed products can be left for one week. And the flame material is easy to obtain, such as the natural gas we usually use can do the job. During the processing, the mixing ratio of air and gas is appropriate so flame temperature can be higher than 1000 degrees Celsius, and the treatment result is positive.

Application

Prior to plastic painting process, surface adhesion quality can be enhanced by flame treatment. Afrer flamming, the coating capacity is greatly improved and more durable.

Flame treatment technology is widely used in automotive industry. For example, it is an important stage of PP car bumper painting line system. Flame treatment can ensure the bumper surface can be well covered by coating. The high quality requirements of automotive industry and extremely harsh working environments require bumpers to withstand impact forces, temperature changes, light and rain etc. At this point, flame treatment technology has proven its value.