Mirror Cap Spray Painting Machine

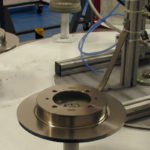

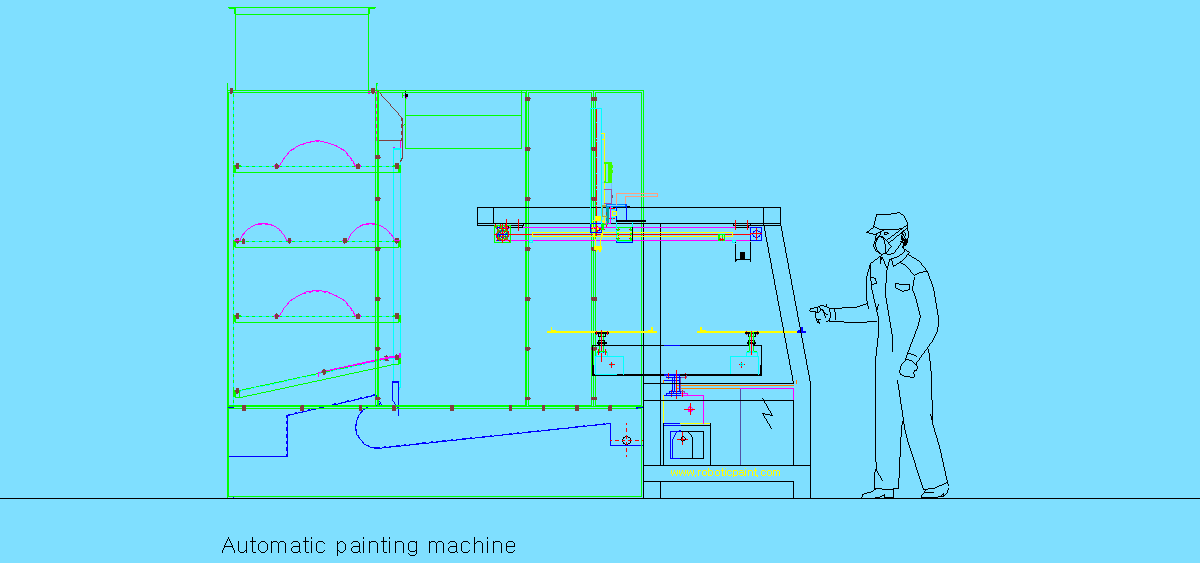

Our Mirror Cap Spray Painting Machine is robotic unit with smart and accurate operation in painting area. The arm be able to handle spray gun in any angle to have the cover painted in high grade quality. It’s widely compatible with various mirror caps spraying requirement and capable of handling medium to high volumn production professionally.

Features:

Can be widely used in painting industry for high rate production. Be able to meet high quality and high efficiency requirements. Completely digital control with up to 100 programs in memory which can be operated easily by man-machine interface.

Operator be able to configure new product painting programs within 15 minutes by friendly GUI operation. No programming knowledge required at all! In this way, customer saved salary to professional engineers for this machine, anyone with simple training can handle the machine professionally!

Painting area is full in spray booth for less waste and easy cleaning. Coating atomizing, CAP and coating supply can be remotely controlled. Spray gun can be used for cleaning purpose too when needed.

Machine configuration details:

- Model: JF-R001

- Name: 6 axis spray painting machine

- Dimension: W2600*D2200*H2250(4 trays); W2200*D1900*H2200(2 trays)

- Applicable coating: Liquid coating

- Control: Automatic

- Fluid rate: 100ml/min

- Spray pressure: 100Mpa

- Speed: 100㎡/h

- Power: 3Kw

- Voltage: 3phase 380v

- Operational temperature: 30℃

- Application: complex shape product

- Air consumption: 100kg/h

- Custom made: Yes

- Weight: 200kg

- Control system: PLC & Touch screen

- Drive: Modules + Gear + Belt

- Servo pack: Yaskawa servo pack

- Coating pump: Graco 308

- Spray gun: Graco or Devilbiss

- Rotation: 90°& 180°

In order to achieve the best painting quality, we recommend to setup space for 100mm between spray gun nozzle and object surface. In this way, the atomized coating can be sprayed to object fastly with less waste.

Mirror cap spray painting machine FAQ

Mirror cap spray painting machine FAQ

How many pieces can be painted concurrently?

Our default jig can hold 6 pieces, the holder can be customly made to meet your requirements.

What’s the popular painting solution for mirror cap?

Automatic painting for car mirror cap can be applied by our reciprocator and painting robot. Manual painting is not recommended for quality control. For coating machine, it will always work in same way after setup so it’s best choice for high quality painting.

What’s the required workflow for complete coating line?

Depends your needed techniques. The popular solution on market are vacuum metalizition coating and automotive coating spray.

For vacuum option, it’s handled by vacuum machine and uv painting line. The process is like this: loading -> dust removal -> uv base coating -> dry up -> vacuum metalizition -> uv top coating -> dry up -> unloading.

After coating treatment, the cover looks like metal producted with high grade reflect.

For automotive coating spray. The process is followed as: loading -> dust removal -> base coating -> IR oven -> top coating -> IR oven -> varnish coating -> dry up -> unloading

This is the most popular option for automotive industry. In this way, some special properties of coating can be showed up perfectly.

How long you can have the machine ready?

We need to know about application requirements first in order to make the suitable design. Normally takes about 2 weeks, it depends the needed components.

How do you pack the machine?

We normally use stretch film and wood box. The packing can be custom made to meet your local requirements.

In need of our Auto Spraying Machine?

Find more about our machine construction details or send us your enquiry now to find out what we can do for you!