Woodware industry is so close to everybody due to its 100% availability in every home and office. Thus the woodware painting is crucial to meet with various standards. In following, we will briefly introduce the main painting solutions used for different types wooden furnitures such as wood board, wooden doors and chair etc.

Roller Coating

Widely used technology for wood board coating. It’s workable for solvent and water base paint on flat conveyor system. Roller is attached with paint then pressed on board. Conveyor system will take the board to pass through drying tunnel directly to get final coated piece. The painting station is pretty fast thus the drying tunnel is relatively long comparing to other painting system configuration. It’s normally setup for mass production demands.

As we see, roller coating solution has some requirements with workshop due to its long size configuration. Due to it’s limitation, it’s only workable for thin wood board products.

Spray Painting Machine

Spraying is the widely used solution which can be deeply custom setup to work with different woodware products. It’s mainly available by stand alone spraying station and conveyorised spraying line setup. Stand alone spraying station can also be various setup such as multi axis spraying machine and a painting robot depends the actual product to work on. The most popular model is our door painting machine which is compatible with lots of wooden products. But for some small size objects like box type products, we will have to use our 5 axis painting machine.

Generally, spraying is always the first choice for high quality surface painting because paint can be evenly applied. Also the spraying unit can be customized by workshop layout instead of a straight line. Spraying and drying unit can be separate for flexible operation.

Disk Painting

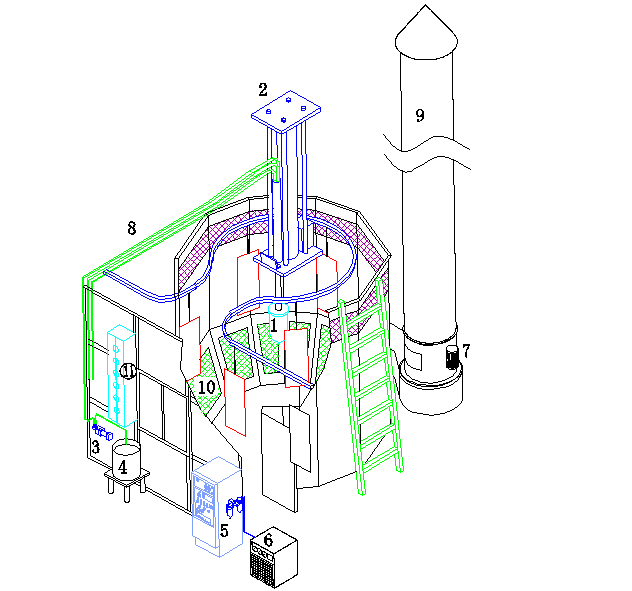

Also known as electrostatic DISK turbo bell painting. The core part is the DISK type paint booth. It’s designed in round shape. When electrostatic turbo bell do up/down reciprocating, objects pass through this area to get coated. Because it’s electrostatic technology, so it’s compatible with complex shaped objects painting such as chair, wood rod and shelf like pieces.

DISK painting can be setup to work with most woodware products by multiple paint booth configuration. But due to it’s technical properties, it’s the most expensive choice in the three options. DISK painting is setup together with hang conveyor system. Depends the actual objects, we can also add after repair spraying booth for some really complex objects dead angle painting.