Wheel Cover Spray Painting Machine Intro

High quality spray painting on wheel cover will simply shine up the entire car. Our spray painting machine is setup for this purpose and fully compatible with factory production for high quality and high efficiency requirement. No matter if you just need for sample painting or high quantity factory production, we can provide you full solutions.

Wheel cover spray painting machine is featured as following:

- Advanced structure for clean and simple control

- Multi-axis are precisely drived by servo motor for accurate positioning

- Digital and module control for air pressure and coating fluid rate

- Small size but big operational space with fast speed

- Can be integrated with other equipments like feeding machine

- Highly flexible to spray each angle smoothly

- Compatible with different products by GUI programming

- Anti-dust unit for clean operation, suitable for clean room installation

- Anti-explosion setup with high class security

- Multiple spray guns applicable for different objects painting

Other than just coating machine, we offer complete wheel cover spray painting line solutions. We can apply different solutions based customer requirements. The regular setup of wheel cover coating line including cleaning, painting and curing system by chain conveyor.

Wheel Cover Spray Painting Line Technical Details

The workflow: Loading -> manual de-dust -> automaitc electrostatic de-dust -> painting -> dryup -> cooling -> unloading

Painting line is composed by conveyor, de-dust unit, spray machine/cabin, clean air supply & waste gas exhaust, dry up oven and control system.

Workflow Explanation

Manual dedust: remove dust on object surface by electrostatic air gun

Electrostatic dedust: Advanced cleaning by static nozzle

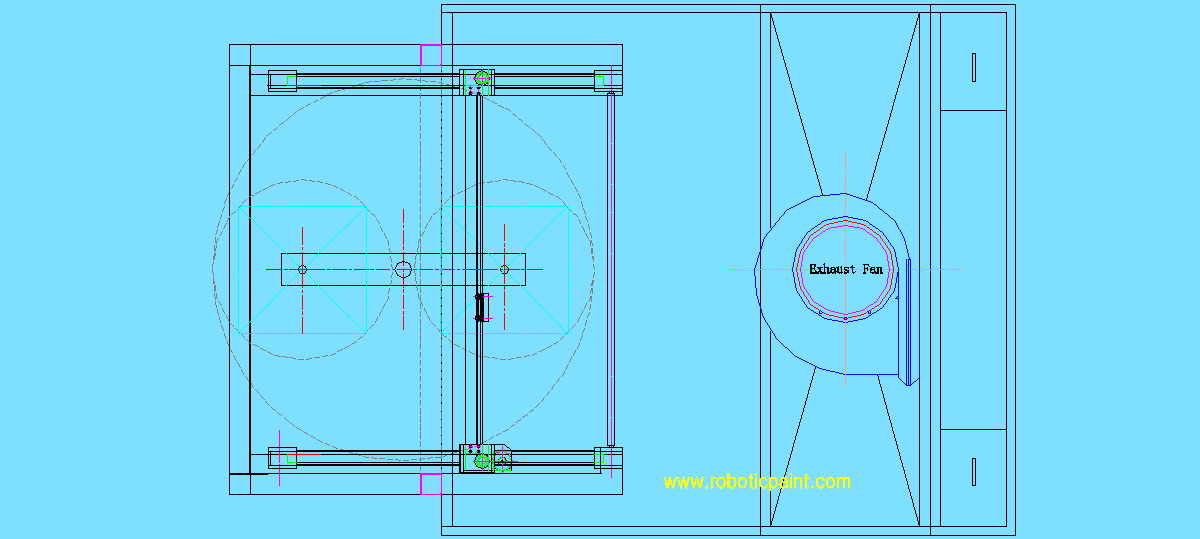

Painting system: automatic spray by coating machine in spray booth with waste gas/water recycling. Control box supplied for seperate control.

Clean air supply: Clean air after multi filter system to make sure no dust in spray area. Waste paint is collected by water or filter bag and make sure no pollution to products.

Dry oven: Conveyor type configuration with heater inside. Temerature is centrally controlled in control box. Temerature difference from inside and door is less than 5 degrees.

Wheel cover spray painting machine FAQ

Wheel cover spray painting machine FAQ

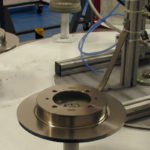

Is it dedicated for wheel cover?

No, the machine is regular reciprocator by seperate programming and holders. But you may need different reciprocators depends wheel cover shapes.

What kind of technology used for wheel cover painting?

Normally it’s spray of automotive grade coating and a varnish coating on surface. You can also apply other technologies such as uv paintig, plating or vacuum coating etc. It completely depends your desired effects.

What kind of spray gun is suggested?

IWATA is regular choice, you can also tell us your requirement and we can help choose the suitable gun for both quality and cost effective.

What’s the machine cost?

We have to learn about your requirements then suggest the best solution. For spare coating machine, the basic price is aruond USD 20000-30000

In need of our Wheel Spraying Machine?

Find more about our machine construction details or send us your enquiry now to find out what we can do for you!