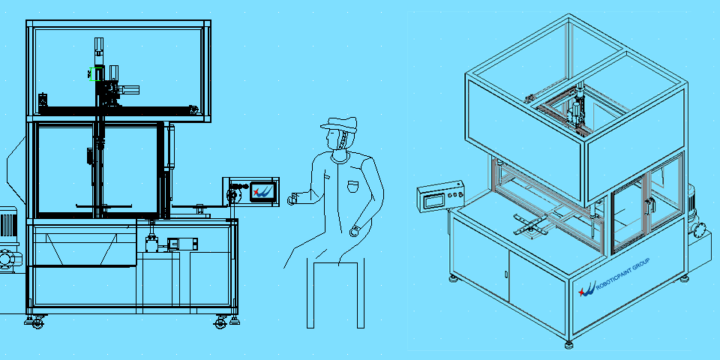

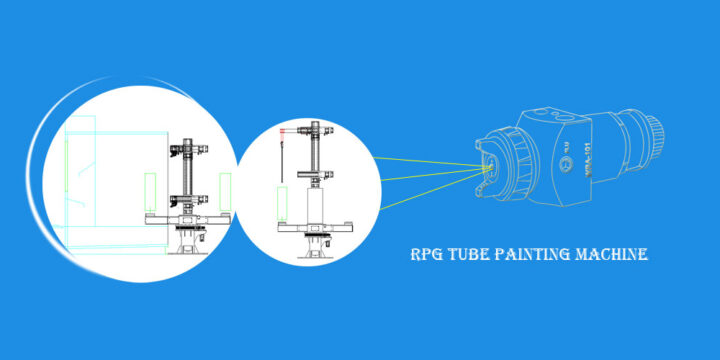

Container Interior & Exterior Painting Machine

[vc_row][vc_column][vc_column_text css=""]Packing container automatic painting machine is a unique design to paint exterior or interior by continuous operation. Easy to operate, no need skilled technician, worker be able to familiar with program setup by just few clicks away. Only a single operator will be able to handle the full production process. By this way production efficiency is greatly improved and labor cost will be reduced. It's widely compatible with lots of container products such as glass cup, stainless steel bottle, flask and pot or barrel etc. Advantages of Container Painting Machine This small size painting machine is central operation on touch screen, small size and easy to use for start up painting factory. Easy installation and fix Small size and suitable for small spray painting processing plants. Meet the spraying…