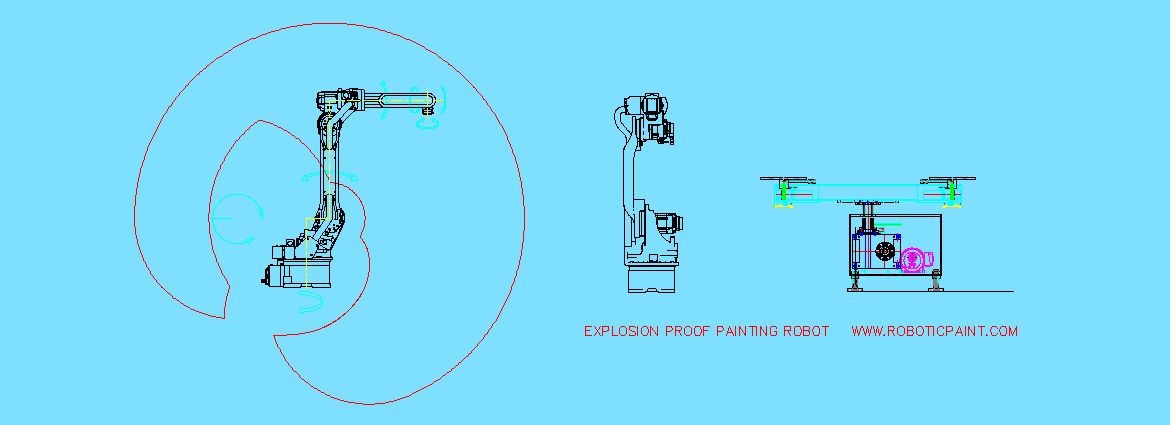

Explosion proof painting robot is a type of industrial robot with explosion-proof capacity design. To make it simply, it is a robot with a high level of security and strong protection capabilities that can adapt to some special working environments. Usually the IP rating is above 54. Painting robot is normally recognized as explosion-proof robot.

When spraying, whether it is powder or paint, in order to ensure its uniformity, it must be atomized. Paint components are all chemical substances, paint mist and volatile other gases are flammable. Paint spraying area is similar to gasoline station which is flammable and explosive. The robot is controlled by electricity. If it is not properly protected, it will cause fire and explosion.

Therefore, in the spraying project, international standards require explosion-proof robots, and the common scenes of explosion-proof robots are also in the spray painting project.

Explosion Proof Painting robot quick details

-

- dimensions: 40 (w) x 80 (h) x 50 (d)cm(minimum size)

- Mass load: 6-10 kg

- Material: Alloy aluminum

- Control panel: 5.7-inch monochrome LCD with emergency stop button and numerical keys

- Chinese/English languages

- iEc Protection class: IP54

- cable Length: 8 m

| Structure | Vertical jointed-arm type | |

| Available axis | 6 | |

| Payload | 6-10kg | |

| Vertical reach | ≥1,052mm | |

| Horizontal reach | ≥860mm | |

| Accuracy | ±0.15mm | |

| Max motion range |

|

±170° +120°/-65° +205°/-165° ±190° ±145° ±360° |

| Max speed |

|

|

| Weight | 50-150kg | |

| Brakes | All axis | |

| Power consumption | 1.5-5KVA | |

| Allowable moment |

|

|

| Allowable moment inertia |

|

|

| Mounting | Floor, ceiling, wall | |

Explosion protection is not just about blocking combustible paint mist, the equipment itself also has requirements for heat dissipation and ventilation. In addition, it should not affect equipment normal operation and maintenance.

From safety view

First of all, no one wants to have a production accident. Everyone has a consensus of safety equipment. Because once an accident occurs, the impact is huge to machine, people and factory. So painting station must be explosion-proof.

From technical means

Does it mean non explosion-proof robot can’t spray? From technical point of view, it’s not the case. We can protect robot easily through various methods, such as adding a protective cover, protective clothing etc to block combustible gas and dust. But explosion-proof is not just to block combustible paint mist, the equipment itself also has requirements for heat dissipation and ventilation. In addition, any configuration should do not affect equipment normal operation.

From national standards

Nowadays, the environmental protection requirements for factories are getting higher and higher. Strict protection standard is a correct thing for continuous development, and it is also the social responsibility and consciousness that every enterprise should bear. Using robots for spraying can increase application rate, reduce resource usage and pollution, thus it’s more environmental friendly choice.

On the other hand, the newly-built spray painting project has rigid requirements for equipment and environmental assessment when it is hold for evaluation. In view of the fact that price of explosion-proof machines is much higher than that of general industrial robots, there are financial supports for industrial enterprises with spraying workshops. They promote enterprise innovation and move toward environmental friendly production methods. This reduced corporate pressure and promotes the process of automation and intelligence.

What are the advantages of explosion-proof painting robot?

Painting robots not only have protective functions but also protective measures. The IP protection level reaches IP55, and the measures for explosion protection are:

- The painting robot cables and motors are all placed inside without being exposed.

- The combustible gas detector is installed in the robot.

- The sealer prevents outside air entering robot housing. When spark and combustible gas are mixed, an explosion will occur. The robot is generally equipped with a combustible gas detector. Once the detector detects a combustible gas, it will alarm and shut down.

Interested in our Explosion-proof Painting Robot?

Find more about our robot construction details or send us your enquiry now to find out what we can do for you!

We need this type of machine for Bangladesh Ordnance Factory.

How to collect and what is the approximate price.

Hi

Would you please share more video for better understanding of this Ex-proof spray painting robot and also tell me that could it be used for stenciling on an oval shape body

Thanks